Fluidized bed coating is a simple, but invaluable process that enhances many of the products we use daily. It offers a durable protective layer to a variety of products from industrial components to consumer goods, making all the difference in performance and longevity. Let’s take a close look at what fluidized bed coating is, how it improves products, and some recognizable items that benefits from it:

What is Fluidized Bed Coating?

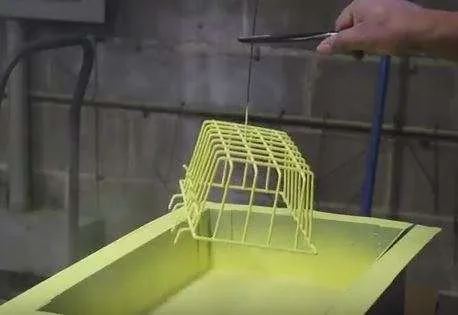

You start with a fluidized bed that contains either polyvinyl chloride or nylon powder with air blown into the bed from the bottom. The air causes the powder to fluidize and then begin to act as though it’s a liquid. The item that is going to be coated is preheated, dipped into the bed, taken out, heated again, and then cooled. This process is mostly used for products that are going to be fully coated.

How Fluidized Bed Coating Improves Products

Industrial Components

Fluidized bed coating is used to improve industrial components, such as pipes, valves, and machinery parts. These items are often exposed to harsh conditions that involve moisture, chemicals, and extreme temperatures. The protective coating provided by fluidized bed coating makes these components more resistant to corrosion, rust, and damage, ultimately extending their lifespan and improving their reliability in demanding environments.

Automotive Parts

Many automotive parts, such as chassis components, bumpers, and fasteners, are coated using fluidized bed coating. The process provides a tough, durable finish that protects the parts from wear and tear, road debris, and exposure to the elements. Fluidized bed coating also enhances the aesthetic appearance of automotive parts by providing a smooth and uniform finish that can be tailored to different colors and textures.

Home Appliances

Another area where fluidized bed coating plays a crucial role is home appliances. Important items such as refrigerators, washing machines, and ovens often feature components that are coated with a layer of protective plastic. This coating helps prevent rust and extends the life of these appliances, ensuring they perform effectively over time. Plus, the coating improves the appliance’s aesthetic appeal by offering a smooth, attractive finish that’s easy to clean.

The Benefits of Fluidized Bed Coating

Fluidized bed coating improves products by offering protection, durability, and aesthetic appeal. It provides an even, high-quality finish that helps items withstand the elements and perform better in their intended environments. Whether it’s a component that needs corrosion resistance, an automotive part that needs durability, or a household appliance that requires an easy-to-maintain surface, fluidized bed coating is the perfect solution.

Fluidized bed coating is an important process that enhances many products that we use each day, making them more durable and functional. If you’re looking for high-quality fluidized bed coating and other plastic manufacturing solutions, Piper Plastics is here to help. We offer expert services in fluidized bed coating, dip molding, and dip coating to ensure your products meet the highest standards. Call 800-966-9919 to get started!