Reinforced plastic has transformed various industries through its strength and versatility. According to a recent report from Grand View Research, the global reinforced plastic market is expected to reach $38.5 billion by 2027. This growth highlights the increasing demand for advanced materials in innovative projects.

Dr. Emily Chen, a leading expert in composite materials, emphasizes that “the adaptability of reinforced plastic is key to its success in modern applications.” Designers and engineers are exploring new possibilities with reinforced plastic, crafting solutions from automotive parts to aerospace components. Its lightweight nature and resistance to corrosion make it an appealing choice for sustainable projects.

However, as the industry evolves, challenges remain. Many professionals still struggle with the processing complexities of reinforced plastic. Furthermore, not all projects fully leverage its potential. Reflecting on these issues can lead to more effective uses and innovations. By understanding both its capabilities and limitations, stakeholders can create more impactful applications for reinforced plastic.

Reinforced plastic is becoming popular in various industries. It combines plastic with fibers, providing strength and flexibility. This material can be five times stronger than steel yet much lighter. According to a report from a leading industry research firm, the global reinforced plastic market is projected to reach $50 billion by 2030. This growth highlights the increasing demand for durable and versatile materials.

Adoption of reinforced plastics varies across sectors. In automotive, using this material can reduce vehicle weight by 25%. This leads to improved fuel efficiency. The construction industry also benefits significantly. Reinforced plastic components can withstand harsh weather, reducing maintenance costs over time. However, not all projects see immediate success. Challenges include material cost and production complexity. Designers must carefully consider these factors to maximize benefits.

While reinforced plastics offer many advantages, there are limitations. They can degrade under UV light if not properly treated. This needs continual oversight during projects. Innovations in this field are ongoing. New methods for enhancing properties are emerging. Still, the balance between cost and performance remains a concern. Working with reinforced plastics requires insight and careful planning.

Reinforced plastic is becoming a game changer in various innovative projects. Its lightweight nature and strength make it perfect for applications in construction and automotive industries. Think about designing eco-friendly buildings. Using reinforced plastic can reduce weight without sacrificing structural integrity. This could lead to advancements in energy efficiency.

In art, reinforced plastic offers creative possibilities. Artists can explore new forms and structures, pushing the boundaries of traditional materials. However, working with this material requires careful planning. It tends to be tricky to mold and shape, sometimes yielding unexpected results. Designers might struggle with achieving the desired finish. Iteration is key; failure can lead to innovative breakthroughs.

Another field to consider is packaging. Reinforced plastic could revolutionize how products are packaged. Companies are shifting towards more sustainable materials. Yet, the challenge remains in balancing durability and recyclability. There’s still much to learn about the lifecycle of reinforced plastic. It is crucial to evaluate the environmental impact fully.

This bar chart illustrates the count of innovative projects utilizing reinforced plastic across various industries, highlighting its prevalence in the automotive sector, followed by construction and consumer goods.

Reinforced plastic is transforming various industries. Its lightweight nature and durability make it a prime candidate for innovative design projects. One notable technique involves using fiber reinforcement. Fiberglass and carbon fiber significantly enhance the strength-to-weight ratio. A recent report states that composite materials like reinforced plastic are projected to grow at a CAGR of 7.8% by 2027.

Another effective method is injection molding. This process allows for intricate shapes and designs. It also reduces material waste during production. According to industry sources, over 45% of reinforced plastic applications are in automotive and aerospace sectors. The challenge remains in ensuring consistent quality across the production line. Inconsistent batch production can lead to weak spots in the final product.

Consider the environmental impact of reinforced plastics. Some projects overlook sustainability. Using recyclable materials can enhance project appeal. As research evolves, new bio-based reinforced plastics emerge, providing options for eco-conscious designs. Adapting these materials requires deeper understanding and trial, as performance can vary. Balancing innovation and responsibility is vital in this evolving field.

| Application | Advantages | Techniques | Considerations |

|---|---|---|---|

| Automotive Parts | Lightweight, corrosion resistance | Injection molding, compression molding | Cost of materials, recycling issues |

| Sports Equipment | Durability, high tensile strength | Lamination, filament winding | User safety, fatigue limits |

| Building Materials | Insulation properties, energy efficiency | Extrusion, thermoforming | Weather resistance, fire safety |

| Medical Devices | Biocompatibility, ease of sterilization | 3D printing, CNC machining | Regulatory compliance, precision requirements |

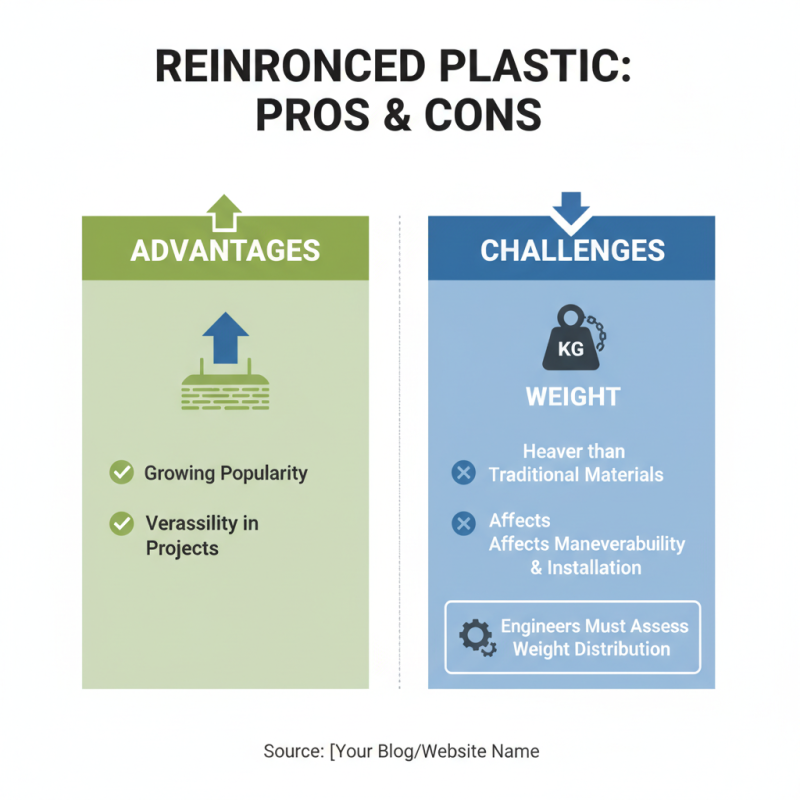

Reinforced plastic is becoming increasingly popular in various projects. However, using this material comes with its own set of challenges. One major issue is the weight of reinforced plastic. It can be heavier than traditional materials, which affects maneuverability. This can lead to complications during installation. Engineers and designers need to address this by carefully assessing weight distribution.

Another challenge is the manufacturing process. Creating reinforced plastic requires specialized techniques. Many teams may lack experience with these methods. This can result in suboptimal product quality or wasted material. Investing in training for team members can help alleviate this issue. Understanding the intricacies of working with reinforced plastic is crucial.

Finally, there are environmental concerns. The production of reinforced plastic can involve harmful chemicals. This necessitates a responsibility to minimize waste and pollution. Seeking sustainable alternatives or recycling options is essential for innovative projects. It’s a complex balancing act that requires ongoing reflection and improvement.

Reinforced plastic has been a game-changer in various innovative projects. One notable example is in the construction sector. A company utilized reinforced plastic in a sustainable building project. The material provided lightweight strength, which reduced transportation costs. However, there were challenges with heat resistance that required further testing.

In the automotive realm, another case shows reinforced plastic being used in vehicle components. This approach improved fuel efficiency. Even so, some components had issues with durability over time, leading to revisions in design. Engineers had to rethink their strategies, emphasizing the material's potential and limitations.

Other industries are also embracing reinforced plastic. In marine applications, reinforced plastic is used for boat hulls. They are lighter and more resistant to corrosion. This innovation, however, raised concerns about overall structural integrity under heavy stress. Such case studies illustrate the exciting yet complex nature of working with reinforced plastic. It offers opportunities for creativity, but also demands careful consideration and adaptation.