In the rapidly evolving landscape of product design and manufacturing, the role of molding experts has become increasingly essential. With a projected market size of $233 billion for the global plastics molding industry by 2024, the expertise in molding techniques and design optimization is more crucial than ever. Research indicates that companies leveraging advanced molding strategies can reduce production costs by up to 30%, highlighting the value of incorporating skilled molding experts into the design process. These professionals are adept at navigating complex challenges, from material selection to process efficiency, ensuring that products not only meet quality standards but also align with market demands. As industries strive for innovative solutions and competitive advantages, unlocking the secrets held by molding experts can significantly enhance overall productivity and product excellence, setting the stage for sustainable growth in today's dynamic market.

In the rapidly evolving landscape of product design and manufacturing, the significance of molding professionals has grown exponentially. As highlighted by a recent study conducted by the American Society of Mechanical Engineers (ASME), the global injection molding market is projected to reach $300 billion by 2025. This surge underscores the necessity for molding experts who possess specialized skills to navigate complex design challenges and optimize manufacturing processes effectively.

Molding professionals today must excel in several key areas, including material science, advanced manufacturing techniques, and software proficiency in CAD and simulation tools. A report from the Society of Plastics Engineers (SPE) indicates that 76% of successful molding projects are directly linked to the expertise of professionals in selecting appropriate materials and understanding their properties. Furthermore, as industries increasingly adopt sustainable practices, knowledge in eco-friendly materials and processes further enhances a molding expert's value. The combination of technical skills and innovation is crucial, as it enables these professionals to contribute significantly to both product functionality and operational efficiency.

| Skill Category | Key Skills | Importance Level | Relevant Tools |

|---|---|---|---|

| Design Skills | CAD Software Proficiency | High | AutoCAD, SolidWorks |

| Manufacturing Process | Molding Techniques | High | Injection Molding, Blow Molding |

| Quality Control | Quality Assurance Techniques | Medium | CMM, SPC |

| Material Knowledge | Material Properties and Selection | High | Polymer Science, Metal Alloys |

| Project Management | Project Planning and Scheduling | Medium | Gantt Charts, MS Project |

Developing effective training programs is crucial to cultivating molding expertise in the manufacturing sector. According to a report by the Society of Plastics Engineers, up to 75% of issues in the molding process can be traced back to inadequate training and skill gaps among operators. To bridge this gap, organizations need to tailor their training sessions to encompass both theoretical knowledge and hands-on experience. This dual approach allows trainees to understand the intricacies of molding processes while also gaining practical skills that can be directly applied in the workplace.

Tips: Incorporate real-world problem-solving scenarios in training programs. This could involve case studies where participants analyze and resolve actual production challenges. Additionally, leveraging technology, such as virtual simulations, can enable trainees to practice molding techniques in a risk-free environment.

Another key aspect is continuous education. As technology in molding evolves, so should training programs. The latest data from the Plastics Industry Association indicates that companies investing in ongoing training report 25% higher productivity levels. Companies should consider implementing refresher courses that cover new materials and techniques, ensuring that their workforce stays ahead of industry advancements.

Tips: Encourage mentoring relationships within teams, pairing inexperienced employees with seasoned professionals for knowledge sharing. Regular feedback and assessments can also help track progress and identify areas for improvement.

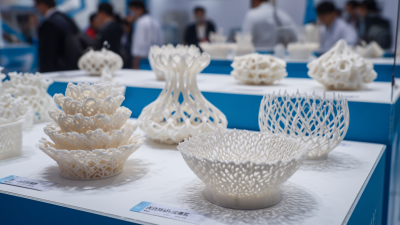

Integrating design thinking with molding techniques is essential for driving innovation in product design and manufacturing. According to a recent report by McKinsey, organizations that embrace design thinking are 1.5 times more likely to convert their ideas into successful products. This approach allows companies to empathize with users, identify their needs, and explore creative solutions. When combined with advanced molding techniques, such as multi-material injection molding and 3D printing, designers can create complex geometries and functions that traditional methods often restrict.

Furthermore, the capabilities of modern molding technologies significantly enhance responsiveness and customization. A study by PwC indicates that 79% of manufacturers believe that adopting advanced manufacturing techniques is crucial for staying competitive. By leveraging design thinking principles, teams can iterate rapidly on prototypes, ultimately reducing time-to-market and aligning closely with consumer demands. This synergy between creative design and efficient manufacturing not only streamlines the development process but also leads to innovative products that resonate more with market trends and user preferences.

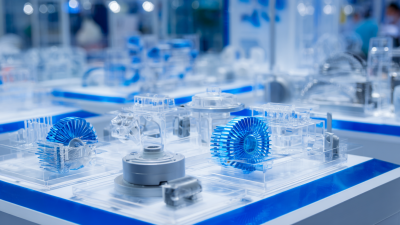

In today's rapidly advancing manufacturing landscape, technology plays a pivotal role in enhancing molding efficiency and quality. With the global automotive mold market valued at $6.53 billion in 2022 and projected to reach $9.12 billion by 2030, a compound annual growth rate (CAGR) of 4.3% from 2024 to 2030 underscores the industry's robust growth. This is largely driven by innovation in manufacturing techniques and the adoption of advanced technologies such as automation, IoT, and AI, which facilitate more precise and efficient production processes.

Sustainability also remains a critical focus within the molding and manufacturing sectors, as companies strive to meet evolving market demands and environmental standards. Reports indicate that the wire drawing mold market is expected to experience a CAGR of 5.5%, reaching a market size of $105.68 million by 2033. By leveraging technology, manufacturers can not only enhance product quality but also align their operations with sustainability objectives, thus securing a competitive edge in an increasingly eco-conscious market. The integration of intelligent production systems, exemplified by smart factories achieving significant efficiency gains, illustrates the transformative potential of these advancements.

This chart illustrates the relationship between various molding technologies and their associated efficiency and quality metrics. The data showcases how different approaches impact productivity and defect rates in product design and manufacturing.

Establishing collaborative processes between designers and molding experts is essential for optimizing product design and manufacturing. Research conducted by the Plastics Industry Association indicates that effective collaboration can enhance product quality by up to 30% while reducing time-to-market by approximately 25%.

When designers engage mold makers early in the design phase, they gain valuable insights into material properties and production capabilities, leading to more innovative and manufacturable designs.

Moreover, according to a study by SME (Society of Manufacturing Engineers), organizations that foster a culture of cross-disciplinary teamwork can see a 50% reduction in design revisions, thereby streamlining the production process. By integrating the expertise of molding professionals, designers can foresee potential manufacturing issues and adapt their designs accordingly, which not only minimizes costly errors but also improves overall efficiency. This collaboration is pivotal in navigating the complexities of modern product development, ensuring that both aesthetic and functional requirements are met without compromising manufacturability.