In the rapidly evolving manufacturing landscape, innovations in plastic casting are set to play a pivotal role in shaping production processes for various industries. As we look ahead to 2025, the advancements in plastic casting technology promise to enhance efficiency, reduce costs, and open new avenues for design flexibility. The integration of cutting-edge techniques and materials is not only accelerating production rates but also improving the overall quality and sustainability of products.

From advanced 3D printing methods to eco-friendly resin formulations, the top innovations in plastic casting are positioned to revolutionize traditional manufacturing paradigms. These developments will enable manufacturers to meet the increasing demand for customized solutions while minimizing waste and energy consumption. As we explore the top five innovations in plastic casting, it becomes clear that these breakthroughs represent more than mere trends; they signify a transformative shift in how products are conceived, created, and delivered to consumers across the globe. Embracing these innovations will be crucial for manufacturers striving to maintain a competitive edge in the years to come.

The push towards biodegradable plastics in casting represents a significant shift in the manufacturing landscape. According to a recent report by MarketsandMarkets, the global biodegradable plastics market is projected to reach $9.3 billion by 2025, growing at a CAGR of 19.9% from 2020. This growth is partly driven by increasing consumer awareness of environmental issues and stricter regulations surrounding plastic waste. Manufacturers are now prioritizing sustainable materials, which not only help in reducing environmental impact but also cater to consumer demand for eco-friendly products.

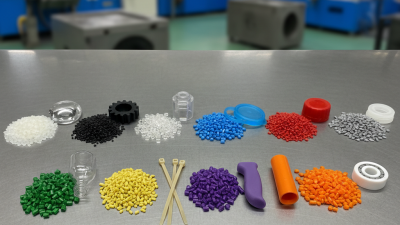

Innovative materials such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are leading the charge in this transformation, offering properties that closely resemble traditional plastics while being compostable. The European Bioplastics Association reported that bio-based and biodegradable plastics together could contribute to a 30% reduction in carbon emissions over the entire lifecycle compared to conventional plastics. As more manufacturers integrate these materials into their casting processes, the industry is poised for a substantial overhaul, aligning production with sustainability goals while maintaining efficiency and performance.

In 2025, the integration of IoT technologies in plastic manufacturing will revolutionize the industry by enabling real-time monitoring and enhanced operational efficiency. Smart technologies allow manufacturers to track the production process, detect anomalies, and optimize resource utilization, resulting in higher quality products and reduced waste. This transformation is crucial as the market for plastic casting evolves, and manufacturers seek to remain competitive in an increasingly demanding environment.

Tips: For manufacturers looking to adopt IoT solutions, it's essential to start with a comprehensive assessment of existing processes. Identify key areas where real-time monitoring could yield the greatest benefits. Additionally, investing in training for staff on new technologies can significantly smooth the transition and ensure that the team is well-equipped to handle advanced systems.

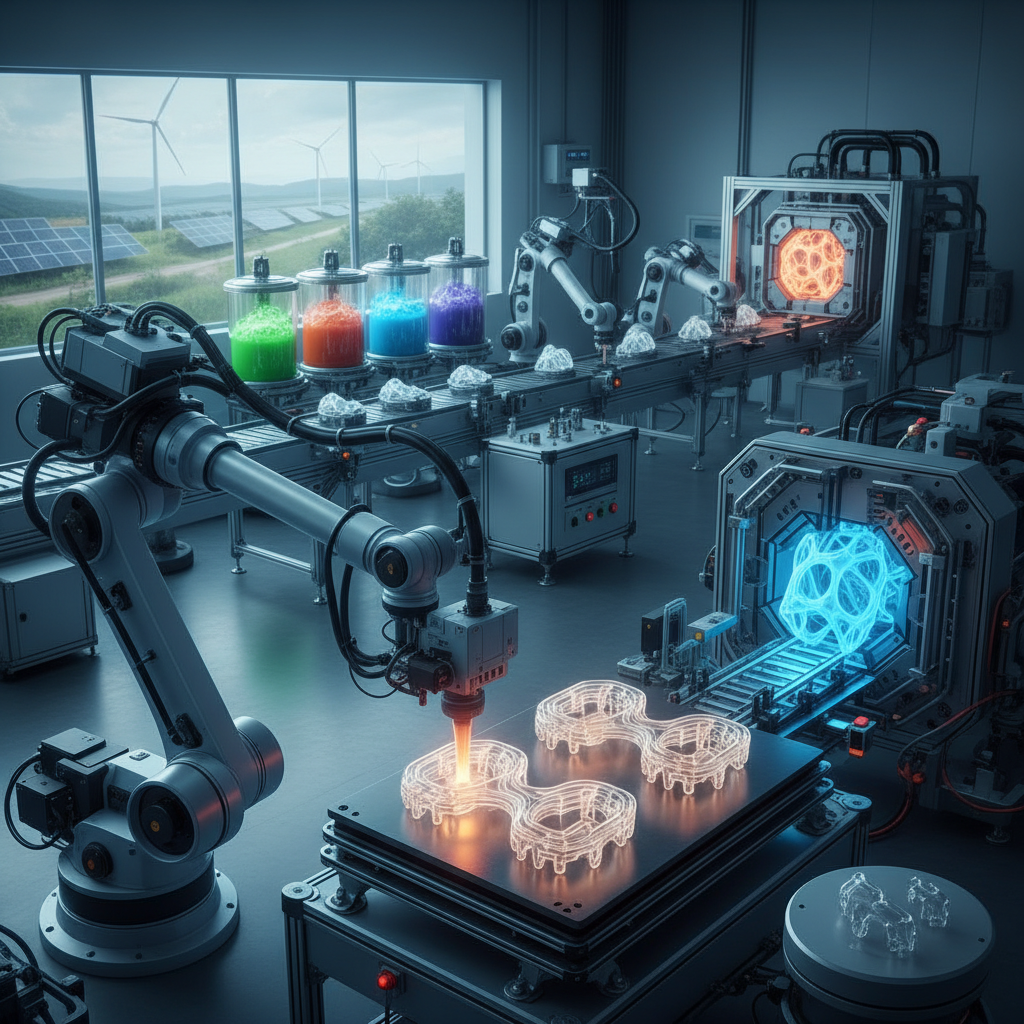

The rising demand for automation in plastic casting goes hand in hand with the improvements brought about by IoT. By connecting sensors and devices throughout the production line, manufacturers can gain insights into operational performance and make data-driven decisions to enhance efficiency. Embracing these innovations will not only streamline production but also drive sustainability in the manufacturing process.

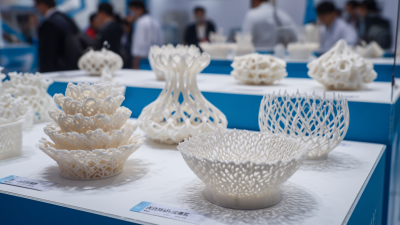

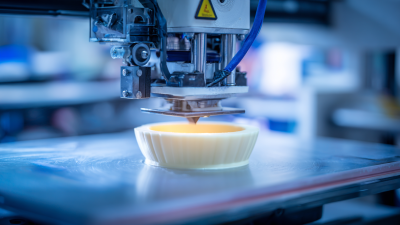

The integration of 3D printing technology into plastic molding processes is set to revolutionize the manufacturing industry. By employing additive manufacturing techniques, companies can produce intricate molds with ease, significantly reducing lead times and costs. Unlike traditional methods that require extensive machining, 3D printing allows for rapid prototyping and customization, enabling manufacturers to respond quickly to market demands. This flexibility is critical as consumer preferences continue to evolve, requiring more unique and tailored products.

Moreover, 3D printing enhances the design possibilities for plastic casting, enabling the creation of complex geometries that were previously unattainable. Designers can experiment with innovative shapes and structures without the constraints of conventional molding techniques. This not only invigorates the creative process but also leads to improved product functionality and performance. As businesses increasingly adopt these advanced molding techniques, the outcome will be a new era of efficient, sustainable production that minimizes waste and maximizes material usage, ultimately transforming the landscape of manufacturing by 2025.

The journey towards sustainability in plastic casting is pivotal for manufacturing industries aiming to reduce their carbon footprint by 30% by 2025. Innovations in materials and methods are key to achieving this target. Biodegradable plastics and recycled materials are increasingly becoming mainstream, facilitating a shift away from traditional, petroleum-based plastics. Implementing energy-efficient processes in production not only minimizes waste but also significantly lowers greenhouse gas emissions.

Tips for manufacturers looking to embrace these sustainable practices include assessing current production methods and identifying areas for improvement. Transitioning to renewable energy sources, such as solar or wind, can drastically reduce energy consumption. Additionally, it's crucial to invest in research and development for innovative casting techniques that enhance efficiency while using sustainable materials.

By fostering a culture of sustainability, manufacturers can align their operational goals with environmental stewardship. Collaborating with suppliers who prioritize sustainable practices can further amplify these efforts, creating a more cohesive and responsible supply chain. Taking these steps can indeed lead to a significant reduction in the carbon footprint associated with plastic casting.

The growing demand for customized plastic parts is set to significantly reshape manufacturing processes by 2025. With a focus on on-demand production, the advancements in plastic casting are creating a pathway for manufacturers to produce tailored solutions that meet specific consumer needs. As highlighted in a recent market research report, the global 3D printed satellite market is expected to reach USD 1582.6 million by 2034, growing at an impressive CAGR of 27.23%. This growth underscores the burgeoning trend of personalized production across various sectors, driven by innovations in plastic casting technologies.

Tips for manufacturers looking to capitalize on customization trends include investing in advanced 3D printing technologies to ensure faster production times and reduced waste. Additionally, leveraging data analytics can help identify consumer preferences and inform design decisions, enabling businesses to stay ahead of market trends. As industries increasingly prioritize sustainability, focusing on eco-friendly materials for plastic casting can also attract a broader customer base and enhance brand reputation.

With the reusable water bottle market projected to reach USD 15.27 billion by 2034, businesses within the industry should explore the potential for customizable designs that cater to health-conscious consumers. By adopting on-demand production techniques, manufacturers can respond quickly to market changes while fulfilling individual customer specifications, thereby maximizing their growth potential in a competitive landscape.