Choosing the right plastic solutions for your business can significantly impact efficiency, product quality, and cost-effectiveness. With a myriad of options available in the market, it becomes crucial to navigate through them thoughtfully to find the best fit for your specific needs. Companies like US Plastic Corp exemplify the variety of plastic products and services that businesses can access, setting a benchmark for quality and reliability.

This article aims to provide a comprehensive guide to help you make informed decisions when selecting plastic solutions. From understanding the different types of materials available to evaluating the functionality and environmental impact, each factor plays a vital role in the decision-making process. By considering these essential tips, you will be better equipped to identify the right products that not only meet your operational requirements but also contribute positively to your overall business objectives.

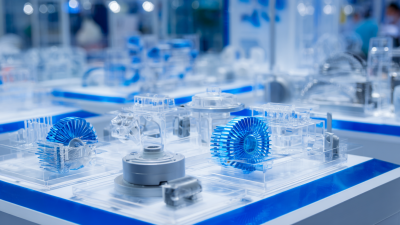

When choosing the right plastic solutions for your business, it's essential to understand the different types of plastic materials available. The global plastic market was valued at approximately $568.9 billion in 2019 and is projected to reach nearly $1 trillion by 2025, indicating a significant demand for various plastic materials. Key categories include thermoplastics and thermosets. Thermoplastics, such as polyethylene and polypropylene, are widely used due to their versatility and recyclability. They can be melted and remolded, which makes them ideal for many applications, from packaging to automotive parts.

On the other hand, thermosets like epoxy and phenolic resins are known for their durability and heat resistance. Once set, they cannot be remolded, making them perfect for applications requiring structural integrity, such as electrical insulators and aerospace components. According to a report by MarketsandMarkets, the thermoplastics segment alone is expected to grow at a CAGR of 4.5% from 2020 to 2025, reflecting the increasing preference for lightweight and energy-efficient materials across various industries. Understanding these differences will enable businesses to select the most appropriate plastic solutions that align with their specific needs and operational goals.

When evaluating your business needs for plastic solutions, the first step is to clearly identify the specific applications and requirements of your operations. Consider the types of products you manufacture or the services you provide, as this will guide you in selecting the right materials. For instance, if your products require durability and resistance to chemicals, you will need to explore options that align with these characteristics. Additionally, think about the lifecycle of the products you create; understanding how they will be used, distributed, and disposed of can influence your material choices.

Another crucial aspect to consider is the volume and scalability of your production. Determine whether your business demands small-batch custom solutions or large-scale production runs. This will help in assessing whether you need standard materials or specialized compounds that can handle higher demands without compromising quality. Furthermore, evaluating the environmental impact of your plastic solutions is becoming increasingly important. Focus on sustainable practices, such as recyclable or biodegradable options, to enhance your brand image and meet customer expectations for environmental responsibility.

| Tip | Description | Business Need | Suggested Plastic Type |

|---|---|---|---|

| 1. Assess Requirements | Evaluate the specific needs for plastic materials in your business. | Durability and longevity of products. | Polypropylene (PP) |

| 2. Consider Cost | Analyze the budget constraints for plastic solutions. | Cost-effectiveness. | Polyethylene (PE) |

| 3. Sustainability | Look for options that are environmentally friendly. | Eco-conscious consumer base. | Bioplastics |

| 4. Supply Chain | Evaluate the reliability of suppliers for your chosen plastic. | Timely production schedules. | Acrylonitrile Butadiene Styrene (ABS) |

| 5. Customization | Determine if custom solutions are necessary. | Unique product requirements. | Polycarbonate (PC) |

| 6. Compliance | Ensure materials meet industry standards and regulations. | Regulatory approval. | Food-Grade Plastics |

| 7. Physical Properties | Choose based on temperature resistance, strength, and flexibility. | Performance needs. | Polyurethane (PU) |

| 8. Aesthetic Qualities | Consider color, finish, and overall look of the product. | Brand image. | PVC with Color Masterbatches |

| 9. Testing | Conduct tests to evaluate material suitability. | Product integrity. | Testing-grade Plastics |

| 10. Future Needs | Plan for potential changes in business requirements. | Scalability. | Flexible Polymer Solutions |

When choosing the right plastic solutions for your business, analyzing the cost-effectiveness of various options is essential. According to a study by Smithers Pira, the global plastic packaging market is projected to reach $1 trillion by 2026, emphasizing the importance of selecting economically viable materials. The total cost of ownership (TCO) should be considered, which includes not only the initial material costs but also factors like manufacturing, transportation, and lifecycle sustainability. For instance, while bioplastics tend to have a higher upfront material cost compared to traditional plastics, their potential for reduced landfill impact and lower regulatory risks can lead to long-term savings.

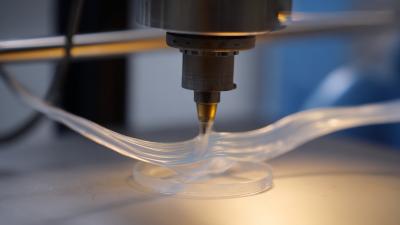

Moreover, the efficiency of manufacturing processes can significantly influence costs. Research from the Plastics Industry Association indicates that advances in injection molding and recycling technologies have made it possible to produce high-quality products at a lower cost than before. In a competitive market, businesses that leverage these advancements can achieve a better return on investment. A detailed analysis of material properties, processing expenses, and disposal options can provide insight into the most cost-effective plastic solutions, guiding businesses in making informed decisions that align with their financial and sustainability goals.

When choosing plastic solutions for your business, it’s crucial to prioritize environmental impact and sustainability practices. The global shift towards eco-friendly materials means that companies must consider their role in reducing plastic waste and pollution. Opting for recyclable or biodegradable plastics not only minimizes harm to the environment but can also enhance a company’s reputation and appeal to environmentally conscious consumers.

Businesses should also evaluate the life cycle of their plastic products, from production to disposal. This includes considering the energy and resources required to manufacture these materials, as well as potential options for repurposing or recycling after their initial use. Partnering with suppliers who prioritize sustainable practices can further ensure that your business aligns with eco-friendly principles. Making informed choices based on sustainability can ultimately lead to long-term benefits for both the environment and your bottom line.

When sourcing plastic solutions for your business, finding reliable suppliers and manufacturers is crucial for ensuring quality and consistency in your products. Start by researching potential suppliers through industry networks, online directories, and trade shows. Pay close attention to their reputation, production capabilities, and lead times. Customer reviews and testimonials can also provide insight into their reliability and the quality of their products. It’s important to engage with multiple suppliers to understand their offerings and compare them based on your specific needs.

Once you’ve narrowed down your options, initiate discussions with your shortlisted manufacturers. A good supplier should be transparent about their production processes, quality control measures, and compliance with industry standards. Request samples to evaluate the quality of materials and ensure they meet your specifications. Additionally, establishing clear communication and building a relationship with your suppliers can lead to better service and collaboration. Don’t overlook the importance of their ability to adapt to changes in demand or unique project requirements, as flexibility can be a vital asset in your sourcing strategy.