Silicone rubber molding represents a revolutionary technique that has transformed various industries through its adaptability and innovative applications. This advanced molding process leverages the unique properties of silicone, such as its flexibility, durability, and resistance to extreme temperatures, making it an ideal choice for a wide range of products.

Silicone rubber molding represents a revolutionary technique that has transformed various industries through its adaptability and innovative applications. This advanced molding process leverages the unique properties of silicone, such as its flexibility, durability, and resistance to extreme temperatures, making it an ideal choice for a wide range of products.

From intricately designed medical devices to robust industrial applications, the versatility of silicone rubber molding plays a crucial role in meeting the demands of modern engineering and manufacturing. In this guide, we will explore its myriad applications, delve into the innovative techniques that enhance its functionality, and provide insights on how to effectively utilize silicone rubber molding to achieve optimal results in your projects.

Whether you're a seasoned professional or a newcomer to this field, understanding the nuances of silicone rubber molding is essential for unlocking its full potential in creating high-quality, durable products.

Silicone rubber molding has garnered significant attention in various industries due to its unique properties and advantages. Notably, silicone rubber boasts exceptional temperature resilience, operating efficiently in temperatures ranging from -60°C to 260°C. This characteristic makes it ideal for applications in the automotive and aerospace sectors, where materials are constantly exposed to extreme conditions. According to a report from Grand View Research, the global silicone rubber market is projected to reach USD 8.6 billion by 2026, which underscores the growing demand and reliance on this versatile material.

Additionally, silicone rubber’s outstanding chemical resistance and durability make it suitable for manufacturing products that require both flexibility and strength. Its non-toxic, hypoallergenic nature further enhances its applicability in the medical and food industries. Innovative techniques such as liquid silicone rubber (LSR) molding allow for more complex designs and intricate component assemblies, improving production efficiency. Industry experts suggest that organizations evaluating silicone rubber applications focus on its compatibility with specific production scenarios to maximize benefits.

Tips: When working with silicone rubber, consider incorporating additives to enhance properties like UV resistance or flame retardancy based on your application requirements. Always ensure proper mold design to optimize the flow of silicone, which can significantly reduce production costs and lead times.

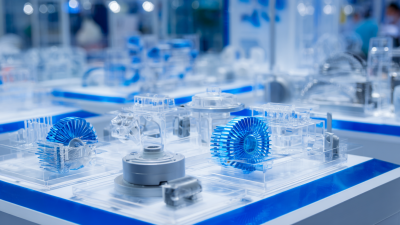

Silicone rubber molding has gained significant traction in various industries due to its superior properties and versatility. According to a recent report by MarketsandMarkets, the global silicone market is projected to reach USD 29.8 billion by 2025, driven by advancements in molding techniques that enhance production efficiency. One of the innovative techniques transforming the landscape of silicone rubber molding is the adoption of liquid silicone rubber (LSR) processing, which permits faster cycle times and higher precision in creating intricate components. This method not only reduces waste but also enables manufacturers to produce complex geometries that were once challenging to achieve.

Another notable technique is the integration of automated and robotic systems in the molding process. This has been shown to increase production rates by up to 30% while also improving consistency in product quality. According to a study published by the International Rubber Conference, automating silicone rubber molding operations leads to substantial labor savings and minimizes human error, further enhancing the overall efficiency of production lines. As industries continue to innovate, the application of these advanced molding techniques positions silicone rubber as a material of choice across automotive, medical, and consumer goods sectors.

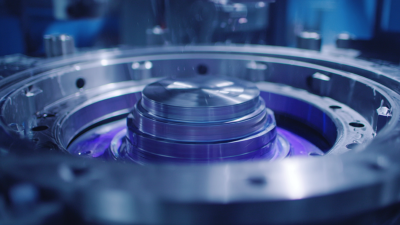

Silicone rubber plays a pivotal role in various industries, particularly in the automotive and aerospace sectors, where reliability and high performance are paramount. In automotive applications, silicone rubber is utilized for gaskets and seals, contributing to engine efficiency and reducing potential leaks. Its ability to withstand extreme temperatures and harsh environments makes it an excellent choice for both interior and exterior components. In the aerospace industry, silicone's lightweight and durable properties are advantageous for seals and insulation materials, ensuring the safety and integrity of aircraft at high altitudes.

**Tips for Choosing Silicone Rubber Applications:**

When selecting silicone rubber for specific applications, consider its temperature resistance and mechanical properties to ensure optimal performance. Conduct thorough testing to evaluate its compatibility with other materials, especially in automotive and aerospace uses, where safety and reliability are critical. Additionally, seek out suppliers that prioritize sustainable practices, as the demand for eco-friendly materials continues to rise in the manufacturing landscape.

Moreover, keep an eye on emerging silicone trends such as innovations in recycling techniques, which are set to reshape the market by 2026. Understanding the evolving landscape of silicone applications will not only benefit operational efficiency but also align with sustainability goals, ensuring a responsible approach to material use in industrial applications.

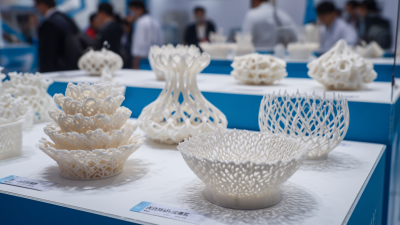

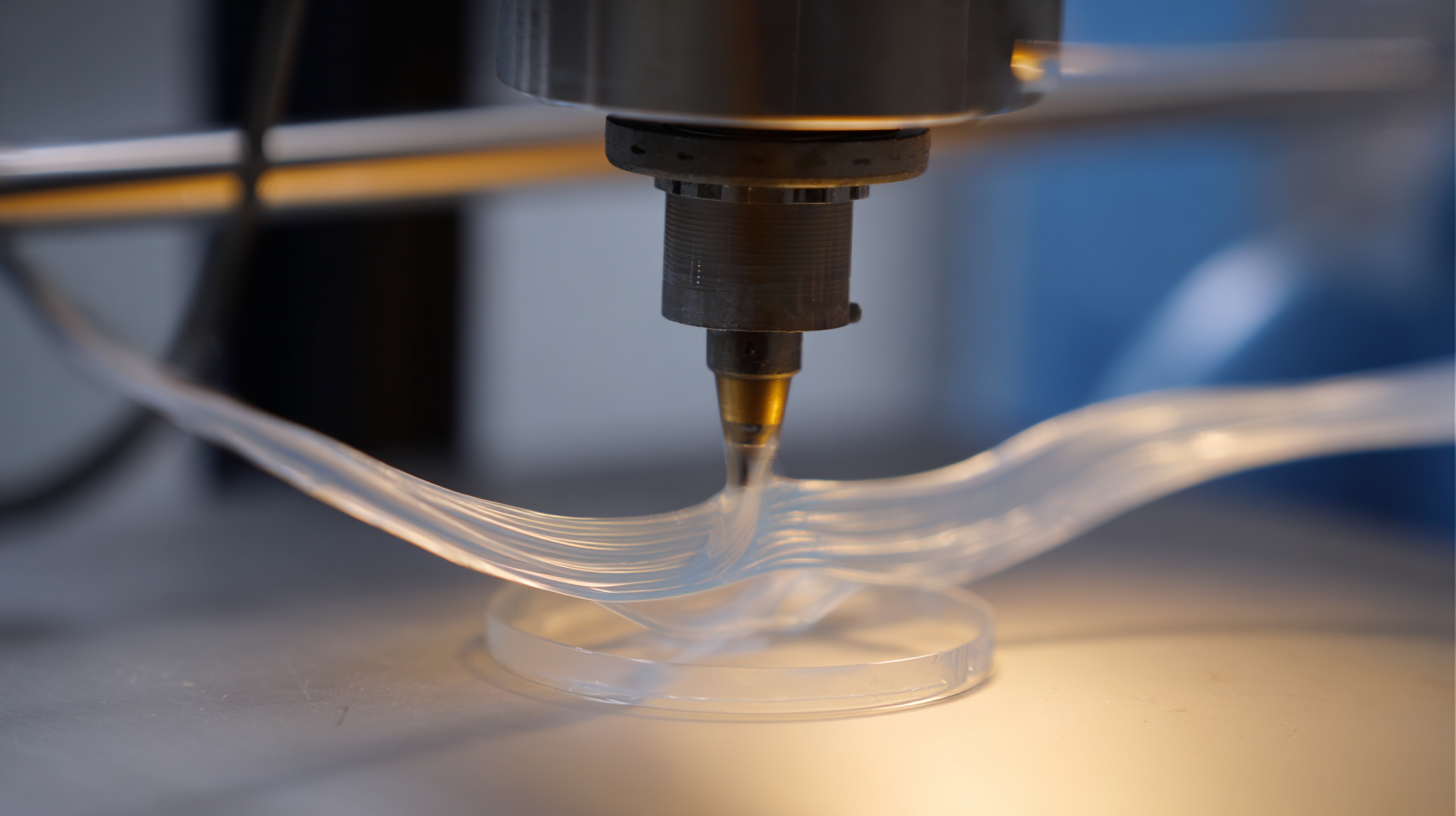

The integration of 3D printing technologies with silicone rubber molding is driving innovative applications across various industries. As 3D printing advances in the production of micro and nano devices, it opens up new avenues for silicone rubber's use in complex, high-precision components. For instance, the ability to create intricate designs and configurations allows for custom silicone products that can cater to specific needs in sectors such as healthcare and electronics. This synergy not only enhances product performance but also reduces manufacturing time and costs.

The integration of 3D printing technologies with silicone rubber molding is driving innovative applications across various industries. As 3D printing advances in the production of micro and nano devices, it opens up new avenues for silicone rubber's use in complex, high-precision components. For instance, the ability to create intricate designs and configurations allows for custom silicone products that can cater to specific needs in sectors such as healthcare and electronics. This synergy not only enhances product performance but also reduces manufacturing time and costs.

Tips: When exploring silicone rubber molding, consider the benefits of using 3D printing for custom specifications. This technique allows for faster prototyping and adaptability in design, which can lead to more optimized production processes. Additionally, staying updated on emerging trends in 3D printing will help you to leverage advancements that can further improve product utility and sustainability.

Another fascinating trend is the growing demand for liquid silicone rubber (LSR), particularly in high-performance applications driven by trends like electric vehicle adoption. As the market is projected to reach new heights, companies investing in R&D will likely find themselves at the forefront of innovation. Embracing these trends not only positions manufacturers for future growth but also aids in creating more sustainable and efficient production methods.

Tips: To stay competitive, regularly analyze industry forecasts and emerging technologies in silicone rubber molding. Engaging with emerging trends can lead to improved product offerings and alignment with market expectations. Collaborating with experts and utilizing innovative tools will also enhance your capabilities in this evolving landscape.

The growing popularity of silicone rubber molding among small to medium enterprises (SMEs) can be attributed to its affordability and versatility. According to a report by MarketsandMarkets, the global silicone rubber market is projected to reach USD 4.7 billion by 2025, growing at a CAGR of 7.5%. For SMEs, adopting silicone rubber molding can significantly reduce production costs while maintaining high-quality outputs. By efficiently using resources and optimizing design processes, businesses can enjoy lower material wastage and faster turnaround times.

Implementing cost-effective strategies for silicone rubber molding involves investing in advanced molding technologies such as injection molding and compression molding. These techniques not only enhance production efficiency but also allow for greater customization in product design. A survey conducted by Research and Markets highlighted that 54% of SMEs that implemented innovative molding techniques experienced a 40% reduction in operational costs within the first year. Additionally, training staff in these technologies can further enhance productivity and innovation, enabling SMEs to compete effectively in the market.