Silicone rubber for mold making has emerged as a preferred material in various industries, thanks to its exceptional flexibility, durability, and ease of use. According to a recent market analysis by Research and Markets, the global silicone rubber market is projected to reach USD 6.63 billion by 2025, with a significant portion of this growth driven by mold-making applications. This surge reflects increasing demand across sectors like automotive, electronics, and consumer goods, where precision and quality are paramount. For beginners venturing into the world of mold making, understanding the properties and applications of silicone rubber is crucial. This guide aims to provide essential tips and techniques to effectively utilize silicone rubber for mold making, empowering newcomers to create high-quality molds with confidence.

Silicone rubber is a favored material for mold making due to its unique properties and versatility. Understanding the different types of silicone rubber is crucial for beginners. Generally, there are two main types: addition-cure silicone and condensation-cure silicone. Addition-cure silicone is known for its excellent detail reproduction and durability, making it ideal for intricate mold designs. In contrast, condensation-cure silicone is more affordable and easier to work with but may not capture fine details as effectively as its counterpart.

In addition to the types, the properties of silicone rubber significantly influence its performance in mold making. Key characteristics include flexibility, temperature resistance, and low shrinkage rates. The flexibility of silicone allows for the easy demolding of complex shapes, while its temperature resistance can accommodate a wide range of casting materials, from resins to plaster. Furthermore, low shrinkage ensures that the molds retain their precision over time, making silicone rubber a reliable choice for both hobbyists and professionals in various applications. Understanding these types and properties will equip beginners with the knowledge needed to select the right silicone rubber for their mold-making projects.

When embarking on mold making using silicone rubber, equipping yourself with the essential tools and materials is crucial for success. According to a report by Smithers Pira, the global market for silicone rubber in mold making has been projected to grow at a 5.2% CAGR from 2021 to 2026. This surge indicates not only the material's popularity but also the increasing need for quality tools among beginners looking to create effective molds.

For novice mold makers, starting with a basic toolkit is important. Essential tools include precision scales for accurate measurements, mixing containers, and a spatula or mixer for combining your silicone components. Additionally, the choice of silicone rubber is pivotal; high-quality products can significantly ease the process. Reports by Grand View Research emphasize that silicone rubber's durability and flexibility make it the preferred choice in various sectors, from automotive to arts and crafts. Furthermore, having a variety of release agents on hand can ensure that your molds come out easily without damage, enhancing your ability to produce multiple pieces efficiently. Investing in these essentials will set a solid foundation for your mold-making journey.

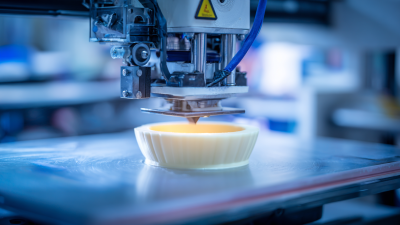

Creating silicone rubber molds can be an exciting and rewarding process for beginners. The first step in making a silicone mold is to prepare your workspace and materials. Ensure that you have silicone rubber, a suitable container for your mold, and any release agents needed to prevent sticking. Start by thoroughly cleaning the original object you want to mold, as any dirt or residue can affect the final result.

Once your setup is ready, mix the silicone rubber according to the manufacturer's instructions, ensuring a consistent blend to avoid bubbles. Carefully pour the mixed silicone over the object in a slow, steady stream to minimize air inclusion. It's essential to let the silicone cure fully, which typically takes several hours or overnight, depending on the product used. After curing, gently remove the mold from the original object, taking care not to damage either the mold or the original. Now, your silicone rubber mold is ready to be used for casting various materials, allowing you to create replicas or unique designs.

When working with silicone rubber for mold making, beginners often make common mistakes that can hinder their results. One mistake is not measuring the silicone and catalyst properly, which can lead to curing issues. It's essential to follow the manufacturer's instructions closely to achieve the desired consistency and curing time.

Another frequent error is neglecting the surface preparation of the original model. Dirt, oil, and moisture can prevent the silicone from adhering properly, leading to defects in the final mold. Always ensure that the model is clean and dry before applying silicone.

**Tips:** To avoid these pitfalls, use a scale to measure components accurately and invest time in cleaning your model thoroughly. Additionally, consider doing a small test pour with silicone on a less critical piece to practice your technique before moving on to more significant projects. This approach will help you build confidence and skill, resulting in successful mold making every time.

When it comes to mold making, understanding the best practices for curing and storing silicone molds is crucial for both durability and performance. Curing silicone rubber properly allows it to achieve its maximum strength and elasticity. According to a report by the American Society for Testing and Materials (ASTM), proper curing can increase the tensile strength of silicone molds by up to 30%. It's essential to follow the manufacturer's recommendations regarding temperature and curing time; typically, room temperature curing can take about 24 hours, while heat-assisted curing might reduce this to a few hours.

When it comes to mold making, understanding the best practices for curing and storing silicone molds is crucial for both durability and performance. Curing silicone rubber properly allows it to achieve its maximum strength and elasticity. According to a report by the American Society for Testing and Materials (ASTM), proper curing can increase the tensile strength of silicone molds by up to 30%. It's essential to follow the manufacturer's recommendations regarding temperature and curing time; typically, room temperature curing can take about 24 hours, while heat-assisted curing might reduce this to a few hours.

In terms of storage, silicone molds should be kept in a cool, dry place away from direct sunlight to prevent degradation of the material. The silicone itself is designed to be flexible and can withstand a wide temperature range, but extreme heat or prolonged exposure to UV light can compromise its integrity. A study from the Journal of Materials Science suggests that storing silicone molds at stable temperatures can enhance their lifespan by over 50%. Additionally, ensure that molds are free of dust and contaminants before storing, as these can adversely affect future casting results.