Rotational molding, an innovative manufacturing process, has significantly evolved over recent years, revealing a plethora of applications across various industries. According to a report by MarketsandMarkets, the rotational molding market is projected to grow from USD 2.4 billion in 2020 to USD 3.3 billion by 2025, highlighting its increasing relevance in modern manufacturing. This process stands out for its ability to produce large, hollow parts with exceptional design flexibility and minimal material waste. Industries ranging from automotive to consumer goods are tapping into the unique benefits of rotational molding, such as enhanced durability and cost-effectiveness in production. As manufacturers continuously seek sustainable and efficient solutions, the secrets of rotational molding become increasingly crucial to understand, paving the way for innovative applications that meet the demands of today's market.

Rotational molding, an innovative manufacturing process, has significantly evolved over recent years, revealing a plethora of applications across various industries. According to a report by MarketsandMarkets, the rotational molding market is projected to grow from USD 2.4 billion in 2020 to USD 3.3 billion by 2025, highlighting its increasing relevance in modern manufacturing. This process stands out for its ability to produce large, hollow parts with exceptional design flexibility and minimal material waste. Industries ranging from automotive to consumer goods are tapping into the unique benefits of rotational molding, such as enhanced durability and cost-effectiveness in production. As manufacturers continuously seek sustainable and efficient solutions, the secrets of rotational molding become increasingly crucial to understand, paving the way for innovative applications that meet the demands of today's market.

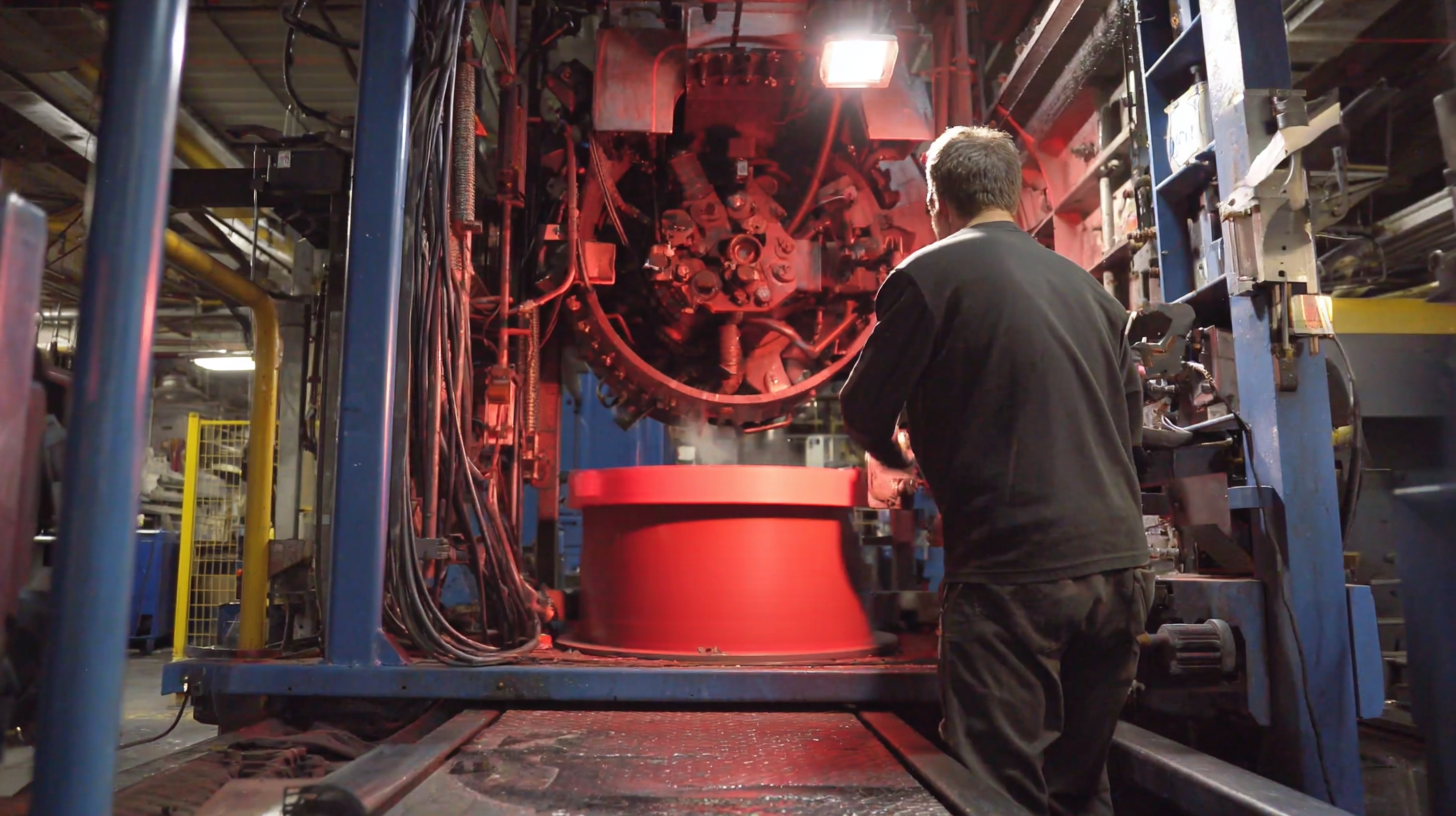

Rotational molding has emerged as a transformative process in the automotive manufacturing industry, offering innovative solutions for producing lightweight and durable components. This method allows manufacturers to create complex shapes with minimal material waste, making it an environmentally friendly option. The versatility of rotational molding enables the production of various automotive parts, from fuel tanks and fenders to interior components. The ability to mold large, hollow structures with a seamless finish makes it particularly attractive for automotive applications, where weight reduction is crucial for improving fuel efficiency and performance.

Moreover, advancements in materials and technology have expanded the range of applications for rotational molding in automotive manufacturing. Manufacturers can now utilize specialty polymers that provide enhanced strength, UV resistance, and chemical stability, which are essential for automotive components exposed to harsh conditions. Additionally, the customization capabilities of rotational molding allow for unique design features that meet specific performance requirements. This adaptability not only helps manufacturers stay competitive but also supports the growing trend toward electric vehicles, where innovative designs and lightweight materials are increasingly in demand.

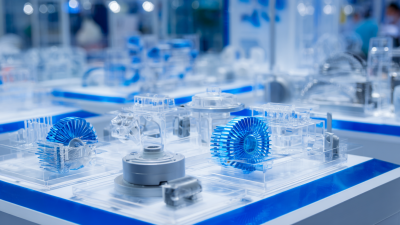

Rotational molding stands out in modern manufacturing due to its unique advantages over traditional methods such as

injection molding and blow molding. One of the primary benefits is the ability to create

complex shapes and large hollow parts with minimal internal stress. This flexibility allows for innovative designs that can be

easily adjusted during the production process, enabling manufacturers to respond quickly to market demands and changes in consumer preferences.

Another significant advantage of rotational molding is the cost-effectiveness in low to medium production runs. Unlike injection molding,

which often requires expensive molds and extensive setup, rotational molding utilizes a single mold for various parts, reducing overall costs. Additionally, it allows for the use of a wide range of materials,

including recycled plastics, which not only lowers material costs but also aligns with sustainability goals within the manufacturing industry. As companies increasingly

seek efficient and environmentally friendly solutions, rotational molding emerges as a powerful alternative that meets both economic and ecological needs.

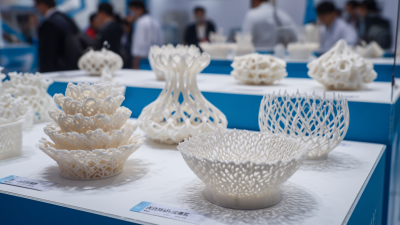

Rotational molding has emerged as a significant player in modern manufacturing due to its environmental sustainability and cost efficiency. This process, characterized by its use of minimal material waste and energy consumption, allows manufacturers to produce a wide range of products with a lower carbon footprint. Unlike traditional manufacturing methods that often involve cutting and shaping materials, rotational molding utilizes a unique technique that reduces excess waste while maintaining high-quality output. By using recyclable materials, companies can further enhance their green credentials, aligning production processes with contemporary environmental standards.

Furthermore, the cost efficiency of rotational molding stems from its ability to produce large quantities of products in a single cycle, reducing labor and operational expenses. The development of quick mold changes and advanced manufacturing technologies has made it easier for companies to adapt to changing market demands without incurring significant costs. Consequently, businesses can achieve economies of scale while also responding swiftly to consumer needs. This combination of sustainability and cost-effectiveness makes rotational molding an attractive choice for manufacturers aiming to innovate while minimizing their environmental impact.

This chart illustrates the various applications of rotational molding along with their environmental sustainability benefits and cost efficiency.

Rotational molding is garnering significant attention in modern manufacturing, driven by its versatility and cost-effectiveness. Industry statistics reveal a robust growth trend in this sector, with a notable increase in demand for custom molded products that cater to unique applications across various industries. From consumer goods to industrial components, rotational molding's ability to create complex shapes with minimal waste is making it an attractive option for manufacturers looking to innovate.

Tips for manufacturers considering rotational molding include evaluating the design for manufacturability early in the process. This ensures that any intricate features are feasible to produce without costly modifications later on. Additionally, maintaining close communication with mold suppliers can lead to insights that improve production efficiency and reduce lead times. Investing in high-quality materials can also enhance the durability and aesthetic appeal of the final product, ultimately delivering greater customer satisfaction.

As businesses seek sustainable practices, rotational molding's reduced material waste and energy-efficient processes play a crucial role in promoting greener manufacturing techniques. By embracing these growth trends and focusing on efficient design and sourcing strategies, manufacturers can leverage rotational molding to meet the evolving demands of the marketplace while benefiting from its unique advantages.

| Data Dimension | 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|---|

| Global Market Size (USD billion) | 6.1 | 6.7 | 7.5 | 8.2 |

| Annual Growth Rate (%) | 4.5 | 5.5 | 6.0 | 6.5 |

| Top Application Sectors | Automotive, Industrial | Consumer Goods, Toys | Medical, Marine | Construction |

| Average Production Time (hours) | 24 | 22 | 20 | 18 |

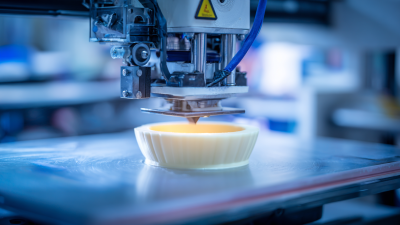

The landscape of rotational molding is evolving rapidly, driven by technological advances that enhance production efficiency and product quality. According to a recent industry report by Grand View Research, the global rotational molding market is expected to reach USD 6.73 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.7%. This growth is attributed to innovations in materials and processes that allow manufacturers to produce more complex geometries with greater precision and reduced waste.

One of the significant future trends in rotational molding is the integration of automation and robotics. Automated systems are beginning to play a crucial role in speeding up production cycles and improving consistency across batches. Additionally, the use of advanced software for design and simulation is paving the way for more sophisticated molds that can accommodate intricate details. Furthermore, the rising demand for sustainable manufacturing practices has led to the adoption of eco-friendly materials, such as bioplastics, which contribute to minimized environmental impact. This shift not only responds to consumer preferences but also positions companies to comply with increasingly stringent environmental regulations.