The manufacturing landscape is undergoing a significant transformation as industries increasingly prioritize sustainability in product design. Among the various manufacturing techniques, rotational molding is emerging as a leading method, particularly for creating innovative, durable, and eco-friendly products. According to a report by the Freedonia Group, the global rotational molding market is expected to reach $7.8 billion by 2024, driven by the rising demand for lightweight, high-performance materials in sectors such as automotive, consumer goods, and packaging. This growth reflects a broader trend towards adopting sustainable manufacturing practices, as rotational molding efficiently utilizes materials and reduces waste. As manufacturers seek to align with environmental regulations and consumer preferences for sustainable products, rotational molding stands out for its ability to deliver complex shapes with minimal material usage, ultimately revolutionizing the future of sustainable product design.

The emergence of rotational molding as a critical technique in sustainable manufacturing practices is transforming the way products are designed and produced. This method, characterized by its low material waste and energy-efficient processes, has gained traction in sectors ranging from automotive to consumer goods. According to a report by MarketsandMarkets, the global rotational molding market is expected to grow from $3.3 billion in 2020 to $4.6 billion by 2025, highlighting its increasing significance in sustainable manufacturing.

One of the key benefits of rotational molding is its ability to utilize recycled materials without compromising quality. The process allows manufacturers to incorporate up to 30% recycled content into their products, significantly reducing their carbon footprint. Additionally, as noted in a study by the Plastic Industry Association, businesses that adopt rotational molding can lower energy consumption by up to 40% compared to traditional molding techniques. This shift not only supports corporate sustainability goals but also meets the rising consumer demand for eco-friendly products. As more companies recognize the advantages of rotational molding, it will likely play a pivotal role in driving the future of sustainable product design.

The rotational molding industry is experiencing a significant shift as it gains momentum over traditional manufacturing methods. This surge can be attributed to the rising demand for sustainable product designs that are not only efficient but also eco-friendly. According to industry reports, the global data center cooling market is expected to grow from $16.84 billion in 2024 to $42.48 billion by 2032. This trend indicates a shift towards more energy-efficient solutions, which aligns with the principles of rotational molding, making it an attractive choice for manufacturers looking to innovate sustainably.

Furthermore, as businesses increasingly focus on reducing their carbon footprint, rotational molding proves advantageous due to its ability to minimize waste and energy consumption during production. The cumulative annual growth rate (CAGR) of markets such as herbal extracts showcases the industry's burgeoning interest in sustainable materials, with a projected CAGR of 8.00% from 2024 to 2030 for angelica root extracts. In tandem with advancements in technology and market demands, rotational molding is positioned to redefine the landscape of manufacturing, allowing companies to meet both consumer expectations and regulatory pressures for sustainable practices.

| Market Trend | Description | Impact on Sustainability | Adoption Rate (%) |

|---|---|---|---|

| Increased Material Efficiency | Rotational molding utilizes materials more efficiently than other methods. | Reduces waste and lowers environmental impact. | 65% |

| Innovation in Materials | Development of bio-based and recycled materials for molding. | Enhances recyclability and reduces reliance on virgin plastics. | 70% |

| Customizability | Allows for complex shapes and designs not feasible with traditional methods. | Enables innovative designs that can reduce production energy use. | 60% |

| Cost Competitiveness | Advancements in technology reducing production costs. | Promotes wider adoption due to lower price points. | 75% |

| Technological Advancements | Integration of automation and digital technologies in molding processes. | Increases operational efficiencies, further reducing carbon footprint. | 80% |

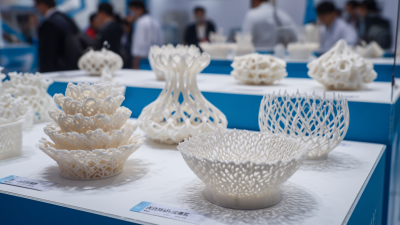

The landscape of rotational molding is undergoing a significant transformation as innovative materials emerge, driving both sustainability and performance. Traditional materials used in this manufacturing process often pose environmental challenges; however, the introduction of bio-based resins and recycled plastics is paving the way for a more responsible approach. These materials not only reduce dependency on fossil fuels but also minimize waste, making a positive impact on the planet. By incorporating these sustainable alternatives, manufacturers can produce high-quality products while adhering to increasingly stringent environmental regulations.

In addition to sustainability, the performance of molded products is enhanced through advancements in material science. New formulations are being developed that improve durability, heat resistance, and flexibility, ensuring that the end products meet consumer demands without compromising on quality. Innovations such as the inclusion of additives that bolster strength and flexibility further broaden the applications of rotationally molded goods. As manufacturers continue to adopt these innovative materials, the future of rotational molding looks promising, with the potential to create a greener, more efficient industry.

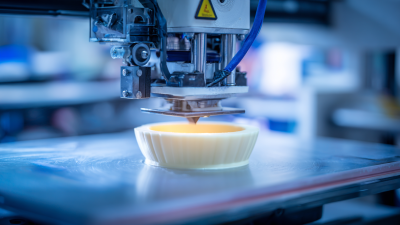

Rotational molding has emerged as a transformative process in sustainable product design, enabling brands to create eco-friendly products without compromising functionality or aesthetics. According to a recent report by the Association of Rotational Molders, the market for rotational molding is projected to reach $2.3 billion by 2025, driven by increasing demand for lightweight, durable materials in various sectors. This process allows for the use of recycled materials, reducing waste and promoting sustainability, which is crucial in today’s environmentally conscious market.

A noteworthy case study is that of a leading outdoor equipment manufacturer that utilized rotational molding to produce a line of biodegradable kayaks. By integrating bioplastics into their manufacturing processes, the company achieved a 30% reduction in carbon emissions compared to traditional plastic kayaks. Additionally, another example can be found in the automotive industry, where rotational molding is employed to create interior vehicle components using recycled polyethylene, resulting in significant weight reductions that enhance fuel efficiency. These case studies illustrate the growing trend of leveraging rotational molding technology to create innovative and environmentally sustainable products that resonate with modern consumer values.

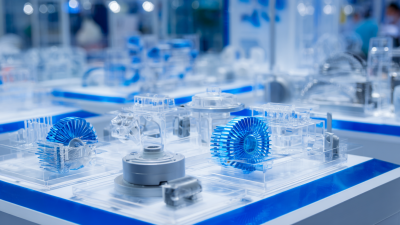

The rotational molding industry is undergoing a significant transformation fueled by advancements in technology. A recent report from Smithers Pira indicates that the global market for rotational molding is projected to reach $3.2 billion by 2026, growing at a CAGR of 5.3% from 2021. This growth is largely driven by innovations in processing techniques and materials, which enhance not only the efficiency of molding processes but also the sustainability of the final products.

Newer technologies such as automated temperature control and real-time monitoring systems are dramatically improving the precision and repeatability of the molding process, resulting in reduced waste and energy consumption.

Newer technologies such as automated temperature control and real-time monitoring systems are dramatically improving the precision and repeatability of the molding process, resulting in reduced waste and energy consumption.

Furthermore, the adoption of biodegradable plastics and recycled materials in rotational molding is reshaping product design towards sustainability. According to a study by the American Plastics Council, the use of recycled materials in manufacturing processes is projected to increase by 35% over the next five years. This trend not only meets the rising consumer demand for eco-friendly products but also positions manufacturers to comply with stricter environmental regulations. As these technologies evolve, we can expect rotational molding to play a pivotal role in the creation of sustainable products, ensuring that the industry not only keeps pace with market demands but also pioneers new standards in environmental stewardship.