In today's competitive manufacturing landscape, the choice of coating techniques can make a significant difference in both product performance and longevity. One such technique that has garnered attention is plastisol dip coating. Renowned industry expert Dr. Emily Carter, a leading authority in surface engineering, emphasizes the benefits of this method, stating, "Plastisol dip coating not only enhances the aesthetic appeal of products but also significantly improves their durability and resistance to corrosion."

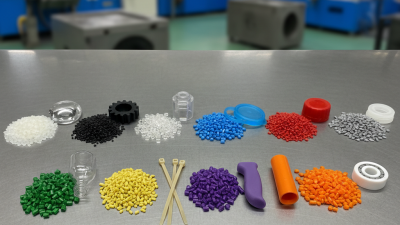

As industries evolve, the demand for coatings that can withstand rigorous conditions without compromising quality continues to grow. Plastisol dip coating offers a unique solution, with its ability to provide a thick, uniform layer that adheres strongly to various substrates. This method is particularly advantageous in applications such as automotive parts, tools, and household items, where protection against wear and environmental factors is crucial.

With its versatility and performance advantages, plastisol dip coating stands out as a preferred choice for manufacturers looking to enhance the functionality and lifespan of their products. By marrying aesthetics with durability, it embodies the modern demands of both consumers and industries alike, making it a top contender for your next project.

Plastisol dip coating has emerged as a preferred finishing technique across a variety of industries, thanks to its versatile applications and numerous advantages. One of the primary benefits of this process is its durability. Plastisol coatings exhibit high resistance to chemicals, corrosion, and abrasions, making them ideal for use in harsh environments. According to a report by MarketsandMarkets, the global market for polymer coatings, including plastisol, is projected to grow significantly, driven by the rising demand for advanced protective coatings in sectors like automotive, aerospace, and construction.

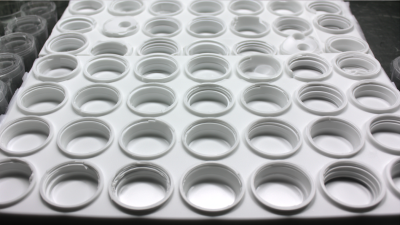

In the automotive industry, plastisol dip coating is frequently used for parts such as handles, knobs, and wire harnesses. This application not only enhances aesthetic appeal but also provides improved grip and reduces noise, crucial factors for manufacturers aiming to meet consumer expectations. Furthermore, a study published by the Industrial Coating Association highlights that coatings applied through dip methods can achieve thickness uniformity essential for long-term performance and protection.

Moreover, the benefits extend to consumer goods, where plastisol coatings are utilized for items such as tools and household products. The soft-touch feel and additional protection against wear contribute significantly to user satisfaction. A survey from the Global Paint and Coatings Industry indicated that the demand for such tailored solutions correlates directly with customer preference for functional yet visually appealing products, emphasizing the relevance of plastisol dip coatings in today’s market landscape.

Plastisol dip coating is an increasingly popular choice in various industries due to its exceptional durability and resistance properties. This versatile coating provides a protective layer that not only enhances the aesthetic appeal of products but also ensures they withstand harsh environmental conditions. The thick layer formed during the dip coating process helps insulate items from moisture, chemicals, and even UV radiation, making it an ideal solution for outdoor applications.

When considering plastisol dip coating for your next project, it's essential to keep in mind its superior adhesion properties. This coating bonds tightly to surfaces, providing a long-lasting finish that resists peeling and cracking. Additionally, the flexibility of the plastisol layer allows it to absorb shocks and impacts, reducing the risk of damage to the underlying material. This makes it particularly beneficial for items that will experience frequent handling or exposure to rough conditions.

Tips for effective plastisol dip coating include ensuring proper surface preparation, which can greatly enhance adhesion. Clean and de-grease surfaces before dipping to remove any contaminants. Furthermore, controlling the temperature during the curing process can optimize the coating's durability and performance. Finally, consider testing various thickness levels to find the perfect balance between protection and flexibility for your specific application.

Plastisol dip coating has become a popular choice in various manufacturing processes due to its versatility and protective properties. This method is commonly used for items that require a durable, non-slip surface. One notable application is in the automotive industry, where components such as handles and knobs are coated to provide both grip and resistance against corrosion. The thick, flexible layer created by plastisol coating enhances the longevity of these parts, making them ideal for demanding environments.

Another significant area where plastisol dip coating is applied is in the production of kitchenware and tools. This coating offers an attractive finish while ensuring that products are safe to handle, even when exposed to heat. Items such as cooking utensils, heat-resistant grips, and bakeware benefit from the insulation and chemical resistance that plastisol provides. Additionally, the vibrant colors available in plastisol coating can enhance product appearance, making them more appealing to consumers. As manufacturers continue to explore new uses, the application possibilities for plastisol dip coating in various sectors remain expansive and promising.

Plastisol dip coating is not only a versatile finishing solution but also a sustainable choice in modern manufacturing. The process involves immersing metal or other substrates into a liquid plastisol that, upon heating, forms a durable and resilient plastic covering. This method minimizes waste and reduces the environmental footprint compared to other coating processes. Since plastisol is typically applied at ambient temperatures, it conserves energy, further enhancing its eco-friendliness.

In addition, plastisol materials are often recyclable, contributing to a circular economy. As industries face increasing pressure to adopt sustainable practices, the longevity and durability of plastisol coatings mean products coated with this material require less frequent replacements, thus yielding significant resource savings over time. Furthermore, the absence of harmful solvents in plastisol formulations minimizes volatile organic compounds (VOCs), promoting healthier working environments and reducing air pollution. With its combination of practicality, durability, and minimal environmental impact, plastisol dip coating stands out as an innovative choice for projects aiming to align with sustainability goals.

When evaluating the cost-effectiveness of coating options, comparing plastisol dip coating to other methods reveals distinct advantages. Plastisol dip coating involves a simple process where a substrate is submerged in a liquid plastisol compound, allowing for a thick, uniform coating that is not only durable but also offers excellent resistance to degradation. The overall expenditure of this method is often lower than alternatives such as powder coating or liquid painting, particularly when considering labor and material waste. The application process is straightforward, requiring minimal machinery and setup, which can significantly reduce overhead costs.

Moreover, while initial material costs for plastisol may be competitive or slightly higher than some coatings, the long-term benefits can lead to substantial savings. Plastisol dip coating exhibits remarkable durability, reducing the frequency and cost of maintenance or re-coating. In contrast, methods like powder coating can involve more complex processes and higher costs associated with surface preparation and curing ovens. By examining the total cost of ownership, including longevity and performance, plastisol dip coating often emerges as a financially savvy choice for many projects, especially those requiring a robust and protective finish.

| Coating Method | Cost per Square Foot | Durability | Application Time | Finish Quality | Best Use Cases |

|---|---|---|---|---|---|

| Plastisol Dip Coating | $5.00 | High | Moderate | Smooth and Flexible | Handles, Handles, and Other Tools |

| Powder Coating | $4.00 | Very High | Long | Durable and Hard | Automotive Parts, Exterior Furniture |

| Liquid Paint | $3.00 | Moderate | Quick | Varied | Interior Surfaces, Decorative Parts |

| Galvanization | $6.00 | Very High | Long | Rough | Industrial Equipment, Fasteners |

| Anodizing | $7.00 | High | Moderate | Smooth and Colorful | Aluminum Parts, Aerospace Components |