The medical molding industry is witnessing a significant transformation as advancements in technology and increased demand for high-quality medical devices drive the need for optimized molding processes. According to a report by Grand View Research, the global market for medical molded products is expected to reach $12.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5% from 2019. This growth underscores the necessity for manufacturers to enhance efficiency in their production processes, ensuring they can meet both regulatory standards and consumer expectations.

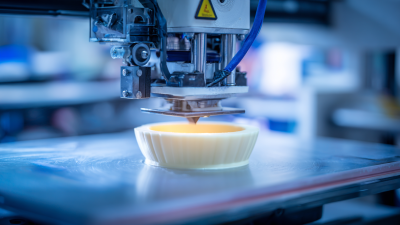

Efficient medical molding is paramount not only for maintaining product quality but also for reducing costs and improving production timelines. Industry data from the Medical Device Manufacturers Association (MDMA) indicates that companies that streamline their molding operations can achieve lead time reductions of up to 30%, offering them a competitive edge in an increasingly crowded marketplace. As the healthcare sector continues to evolve with the integration of newer materials and technologies, such as 3D printing and automation, the potential for optimizing medical molding processes has never been greater.

In this context, understanding the principles of medical molding efficiency becomes crucial for stakeholders in the industry. By focusing on best practices in design, material selection, and process management, companies can not only enhance operational performance but also uphold the highest standards of safety and efficacy in the production of medical devices. Embracing these advancements and strategies will ultimately position organizations to thrive in the fast-paced medical molding landscape of 2025 and beyond.

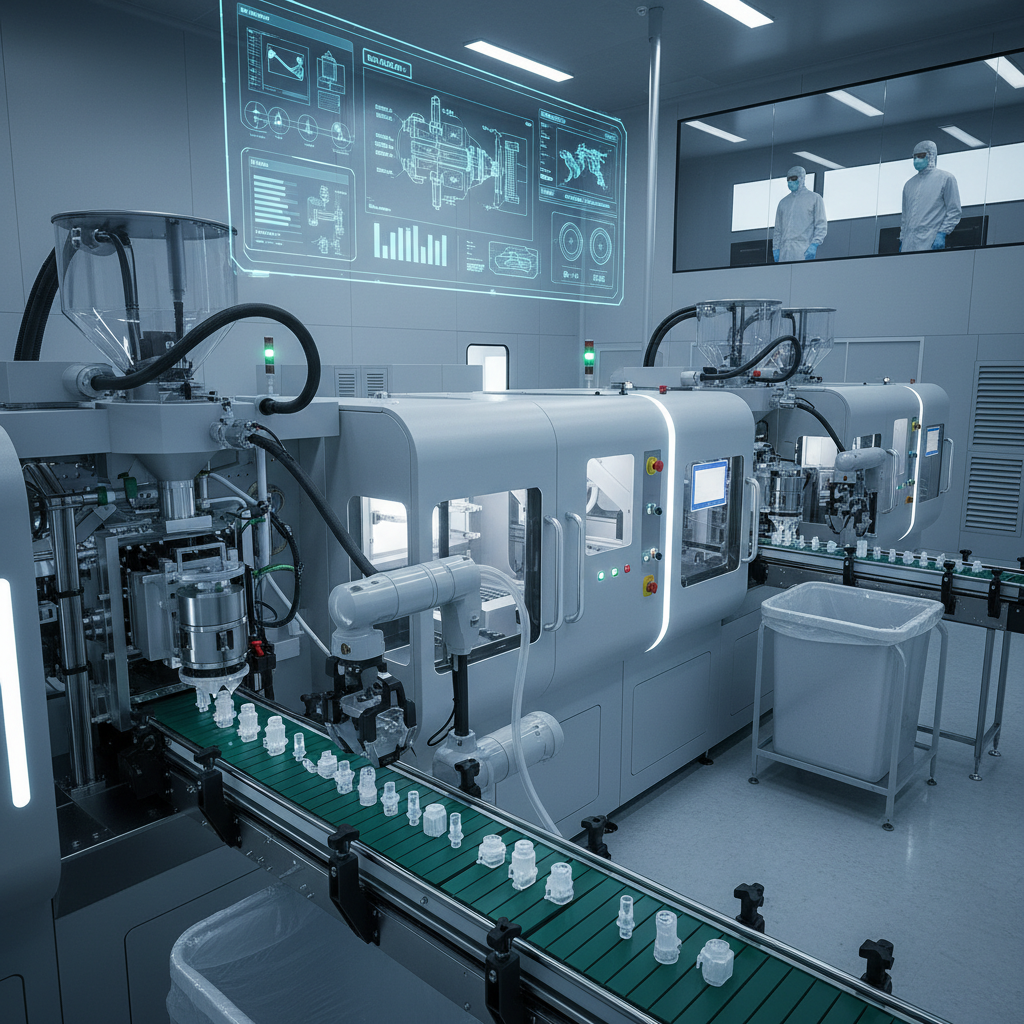

In the highly regulated medical manufacturing industry, optimizing molding processes is critical for enhancing workflow efficiency. According to a recent report by Grand View Research, the global medical molding market is expected to reach $35.9 billion by 2027, driven by increasing demand for precision-engineered medical devices.

One effective strategy to streamline this process involves implementing advanced automation technologies. Utilizing robotics for tasks such as material handling and quality inspection can significantly reduce cycle times and minimize human error. A study by the Advanced Technology Institute revealed that companies adopting automation have seen up to a 30% increase in production speed.

Another key strategy is the adoption of data-driven decision-making through real-time analytics. By employing IoT sensors, manufacturers can monitor the molding process continuously, allowing for immediate adjustments to be made that enhance efficiency and reduce waste. A report from McKinsey highlights that organizations leveraging big data analytics can improve their operational efficiency by 20-30%. This approach not only ensures the quality and compliance required in medical applications but also contributes to cost savings and faster time-to-market for new products.

As the medical molding sector continues to evolve, embracing these strategies will be essential for maintaining a competitive edge.

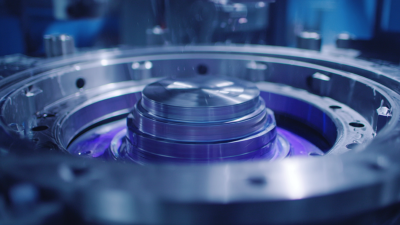

Technological innovations are significantly enhancing precision in medical molding processes, a critical aspect of the medical device industry. With the global micro injection molding machine market expected to grow substantially, companies are increasingly focusing on optimizing their molding processes to achieve greater efficiency. These advancements not only lead to cost savings but also improve the overall quality and reliability of medical devices, which are vital for patient safety.

Tips for optimizing medical molding processes include investing in the latest molding technologies and automation. Implementing advanced monitoring systems can also help detect issues in real-time, minimizing defects and ensuring high precision. Additionally, collaborating with Contract Manufacturing Organizations (CMOs) can enhance access to state-of-the-art methods and expert knowledge, ultimately streamlining the production pipeline.

As the medical device industry continues to expand, innovations like precision injection molding are expected to play a pivotal role. Companies, such as those partnering within equity platforms, are actively seeking to leverage these advancements, aiming for streamlined designs and faster turnaround times, meeting the growing demand for complex medical technologies.

In the context of optimizing medical molding processes for maximum efficiency,

material selection plays a crucial role. The ongoing challenges in the market,

such as strict environmental regulations and rising landfill costs, emphasize the importance of sustainable practices.

For instance, the adoption of lifecycle assessments is becoming prevalent across various industries,

enabling companies to evaluate the environmental impact of materials over their entire lifespan. This approach not only aids in material selection

but also fosters waste reduction, which is essential for achieving compliance with stringent environmental policies.

Additionally, looking at the broader landscape of packaging, the artificial intelligence packaging market

is projected to reach a value of $2.4 billion in 2024, growing at a compound annual growth rate of over 10.1%

from 2025 to 2034. This growth is driven by an increasing demand for supply chain transparency

and packaging traceability. As manufacturers seek to innovate while adhering to eco-friendly principles,

the integration of advanced technologies into packaging solutions can significantly mitigate waste and enhance recycling efforts,

thus aligning with the waste reduction initiatives required in medical molding processes.

Implementing lean manufacturing principles in medical molding processes can significantly enhance efficiency and reduce waste. Lean manufacturing focuses on optimizing workflows and eliminating non-value-added activities, which is crucial in the highly regulated medical industry. By leveraging tools such as value stream mapping, manufacturers can identify bottlenecks and streamline operations, ultimately leading to faster cycle times and improved product quality.

Tips for Efficient Lean Implementation:

1. Educate your team on lean principles: Ensure that all employees understand the basics of lean manufacturing, as their involvement is crucial for successful implementation. Regular training sessions can cultivate a culture of continuous improvement.

2. Use 5S methodology: Implement the 5S system (Sort, Set in order, Shine, Standardize, Sustain) to organize the workspace. This practice minimizes clutter, ensures that the necessary tools are easily accessible, and enhances overall productivity.

Incorporating lean principles also involves fostering collaboration between departments. Cross-functional teams can drive process improvements by sharing insights and identifying areas for enhancement, leading to more cohesive and efficient molding processes tailored to meet the demands of the medical sector.

Optimizing medical molding processes is crucial for achieving maximum efficiency and maintaining high standards for product quality. To measure the success of optimization efforts, several key metrics must be tracked. These metrics typically include yield rates, cycle times, and scrap rates. By monitoring these indicators, manufacturers can pinpoint areas for improvement and adjust their processes accordingly.

**Tips:** Regularly conducting data analysis on yield rates will help identify production inefficiencies. Aim for a yield rate above 95% to ensure that most molded products meet quality standards. Additionally, tracking cycle times can shed light on bottlenecks in the production process. Reducing cycle times by just a few seconds can significantly boost overall output.

Implementing a robust scrap rate assessment is also vital. A low scrap rate not only reduces material costs but also indicates effective process control. To enhance performance, consider adopting lean manufacturing principles and continuous improvement strategies that encourage feedback and innovation within the production team.

| Metric | Description | Target Value | Current Value | Status |

|---|---|---|---|---|

| Cycle Time | Time taken to complete one molding cycle | 30 seconds | 35 seconds | 🔴 Below Target |

| Scrap Rate | Percentage of defective molded parts | 2% | 5% | 🔴 Above Target |

| OEE (Overall Equipment Effectiveness) | Comprehensive measure of manufacturing efficiency | 85% | 78% | 🔴 Below Target |

| Downtime | Total time when production is halted | Less than 2 hours/week | 3 hours/week | 🔴 Above Target |

| Cost per Unit | Average cost incurred to produce each part | $1.50 | $1.75 | 🔴 Above Target |