In the world of crafting and artistry, mold making stands out as a vital technique that allows artisans to transform their creative visions into tangible works of art. Mastering the nuanced art of mold making not only enhances an artisan's skill set but also opens up a myriad of innovative possibilities for capturing intricate designs and shapes.

This guide aims to unravel the complexities of mold making, providing aspiring artisans with essential techniques and valuable tips to refine their craft. From understanding the selection of materials to exploring advanced methods, we will delve into how effective mold making serves as a foundation for various artistic pursuits.

Whether you are a novice eager to learn or an experienced artist looking to expand your repertoire, the insights shared here will empower you to embrace the art of mold making with confidence and creativity.

Whether you are a novice eager to learn or an experienced artist looking to expand your repertoire, the insights shared here will empower you to embrace the art of mold making with confidence and creativity.

When embarking on the journey of mold making, one of the crucial steps is selecting the right materials that align with your creative vision and project requirements. Each type of mold-making substance possesses unique characteristics that can drastically impact the quality and durability of the final product. Silicone rubber, for instance, is favored for its flexibility and detail reproduction, making it ideal for intricate designs. Its ability to withstand high temperatures also opens up a broader range of casting materials, from resin to plaster.

In contrast, urethane rubber offers a faster curing time and exceptional strength, suitable for functional molds that require repeated use. Additionally, exploring natural materials such as alginate can yield striking, biodegradable molds perfect for temporary projects or educational purposes. By understanding the properties of these materials, aspiring artisans can make informed choices that enhance their mold-making experience and lead to innovative results. The right substance not only supports the technical demands of your project but also allows for greater creativity and experimentation.

When embarking on the journey of mold making, having the right tools is crucial for achieving precision and creativity in your projects. Essential tools for mold making include a variety of crafting implements such as spatulas, mixing cups, and measuring tools. Spatulas allow artisans to evenly spread and manipulate materials, while mixing cups are vital for accurately measuring components of mold-making compounds like silicone and resin. Additionally, a digital scale can ensure that your mixtures are perfectly balanced, leading to better results.

Another fundamental category of tools encompasses mold-making materials themselves. High-quality silicone rubber and thermoplastics are popular choices due to their flexibility and durability. Investing in different types of release agents can also significantly improve your workflow, preventing stickiness and ensuring that your molds release cleanly. For more intricate designs, incorporating sculpting tools and heat guns can help refine details and achieve desired textures. By equipping yourself with these essential tools, you will be well-prepared to explore the innovative techniques that mold making has to offer.

| Tool | Description | Uses | Price Range |

|---|---|---|---|

| Silicone Rubber | Flexible material used for creating molds. | Casting various materials such as resin and plaster. | $20 - $100 |

| Release Agent | Substance applied to mold surfaces to prevent sticking. | Ensuring easy removal of casted items. | $10 - $30 |

| Mold Box | Container used to hold mold material during curing. | Defining the shape and dimensions of the mold. | $15 - $50 |

| Mixing Tools | Tools for mixing mold material components. | Ensures proper consistency of materials. | $5 - $25 |

| Vacuum Chamber | Equipment for removing air bubbles from mold material. | Improves the quality and detail of the mold. | $100 - $500 |

Creating your first mold can seem daunting, but with a step-by-step approach, you can master this essential skill in the world of artisan crafting. According to a 2021 report by the National Association of Manufacturers, the demand for precision molds in the craft industry has increased by over 20% in the last five years. This highlights not only the growth in opportunities for aspiring artisans but also the importance of high-quality mold-making techniques.

To start, gather essential materials such as silicone or polyurethane rubber, a mixing container, and a release agent. Begin by preparing your model, ensuring it is free of dust and imperfections for a seamless mold. Once your materials are ready, follow the manufacturer’s instructions for mixing the rubber, taking care to achieve the right consistency.

Pour the mixture slowly over your model, allowing it to fill any intricate details. As you develop your skills, you’ll find that mastering the art of mold-making not only improves your craftsmanship but also significantly enhances the quality of your finished products, meeting the increasing market demand for artisanal goods.

Mold making is a rewarding yet intricate process, and aspiring artisans often encounter common pitfalls that can hinder their progress. One frequent mistake is not adequately preparing the original model. Ensure your model is clean, smooth, and completely dry before applying the mold material. Any imperfections will be transferred to the mold, ultimately affecting the final product.

Another common error is neglecting to consider the mold material's properties. Choosing the wrong type can lead to issues like tearing or poor detail capture. Research various materials to find one that suits the specifics of your project. For example, silicone is excellent for flexible molds, while polyurethane may be better for rigid designs.

**Tips:** Always perform a small test before committing to a larger project. This will give you a better understanding of how the materials interact. Additionally, invest time in measuring and mixing materials accurately; inconsistency can lead to undesirable results. Lastly, take your time during the curing process; rushing this step can compromise the mold's integrity, affecting the quality of your casts.

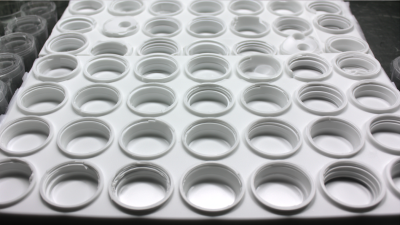

Innovative techniques in mold making are revolutionizing the way aspiring artisans approach their craft. One such technique is the use of silicone rubber molds, which provides unmatched flexibility and detail. This material captures intricate designs and allows for easy demolding, making it ideal for complex shapes. Additionally, silicone molds can be reused multiple times, reducing material waste and production costs, an important factor for artisans looking to streamline their process.

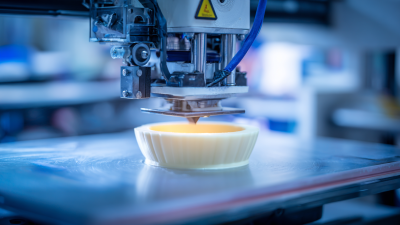

Another exciting advancement is the integration of digital tools in mold making. 3D printing technology enables artisans to design and produce precise molds tailored to their specific needs. This not only speeds up the creation process but also opens up possibilities for unique, custom designs that were once difficult to achieve. By using CAD software to visualize and modify their designs, artisans can experiment freely, optimizing their molds for various applications. Embracing these innovative techniques empowers aspiring mold makers to elevate their skills and expand their creative horizons.