The 2025 China Import and Export Fair, also known as the 138th Canton Fair, is set to highlight significant advancements in the manufacturing and application of plastic parts, a sector projected to reach a compound annual growth rate (CAGR) of 4.5% by 2027, according to a recent market analysis report by Grand View Research. As industries increasingly prioritize sustainability, innovations in plastic parts are leading the way, with the market for biodegradable plastics anticipated to grow substantially.

The Fair will serve as a pivotal platform for showcasing cutting-edge technologies and materials, allowing manufacturers and suppliers to connect and explore novel solutions that not only enhance product performance but also comply with stringent environmental standards. With China being a major player in the global plastic parts market, this event is crucial for understanding upcoming trends and fostering successful international collaborations in plastic manufacturing.

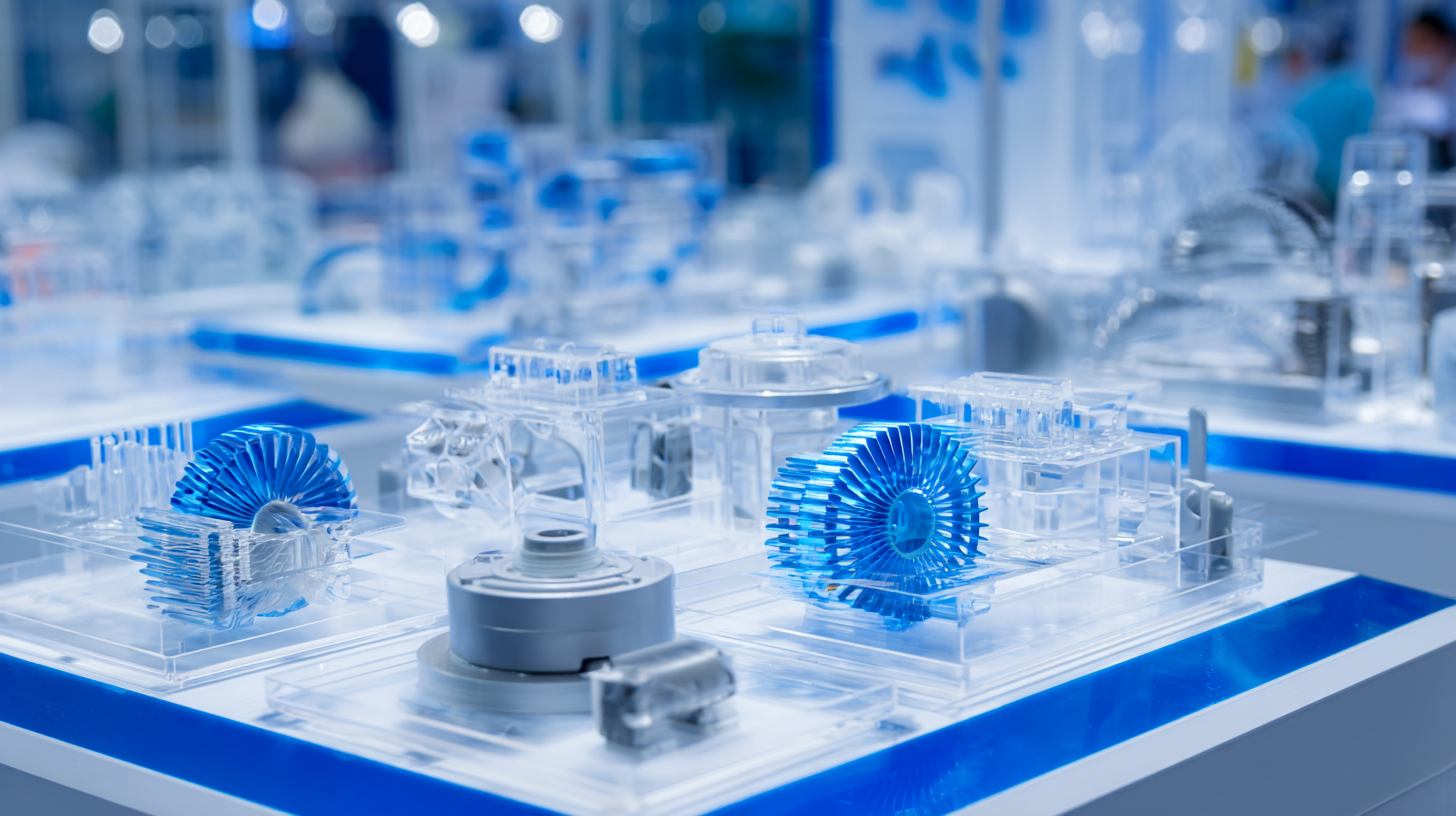

At the 2025 China Import and Export Fair, a wave of innovative plastic manufacturing techniques took center stage, reflecting the industry's commitment to sustainability and efficiency. The fair highlighted advancements such as 3D printing and bioplastics, which are revolutionizing traditional manufacturing processes. According to a recent market analysis by Grand View Research, the global 3D printing plastics market is expected to reach USD 1.4 billion by 2026, growing at a CAGR of 20.0%. This growth is driven by the rising demand for custom and complex designs, making 3D printing an increasingly viable option for manufacturers.

Moreover, bioplastics emerged as a crucial topic at the fair, with a report from Research and Markets indicating that the bioplastics market is anticipated to surpass USD 25 billion by 2027. The focus on eco-friendly materials is in response to the increasing pressure from consumers and regulatory bodies to reduce plastic waste. Exhibitors showcased innovative materials derived from renewable resources that do not compromise on performance, potentially transforming how industries approach plastic production. This year's fair not only spotlighted advancements but also set the stage for a more sustainable future in plastic manufacturing.

The exploration of sustainable materials is redefining the landscape of plastic parts in modern industries. As global awareness of environmental issues rises, manufacturers are increasingly seeking alternatives to traditional plastics, which are often derived from fossil fuels and contribute to pollution. Innovations in bioplastics, recycled materials, and biodegradable options are taking center stage, illustrating a commitment to sustainability without compromising performance.

At the 2025 China Import and Export Fair, industry leaders are expected to showcase cutting-edge advancements that highlight the utility of sustainable materials in plastic production. These innovations not only address ecological concerns but also meet the growing demand for high-quality, durable plastic components. By integrating renewable resources and implementing circular economy principles, companies are not only enhancing their product offerings but also promoting a more responsible approach to manufacturing that aligns with global sustainability goals.

At the forefront of industrial innovation, the 2025 China Import and Export Fair will showcase groundbreaking advancements in plastic parts design and functionality. The integration of smart materials and additive manufacturing has led to a significant transformation in the production processes. According to a recent report by the Global Plastic Innovations Association, the utilization of 3D printing technologies has increased by 35% in recent years, allowing manufacturers to create intricate designs that were previously impossible with traditional methods. This not only enhances the aesthetic appeal but also optimizes the functional performance of plastic components.

One of the key technological advancements driving this evolution is the development of biodegradable plastics. As consumer awareness of environmental sustainability grows, the demand for eco-friendly materials has surged. The Bioplastics Industry Report 2023 highlights that the market for biodegradable plastics is expected to reach $15 billion by 2026, with innovations in polymer chemistry leading the way. By choosing materials that decompose naturally, companies are not only reducing their ecological footprint but also appealing to a conscientious consumer base.

Tips: When considering innovations in plastic parts, it's essential to stay updated on industry trends and sustainable practices. Engage with local suppliers who specialize in eco-friendly materials and explore collaborations with tech firms skilled in additive manufacturing. These strategies can foster creativity in design while meeting the growing demand for sustainability.

| Innovation Type | Description | Material Used | Applications | Sustainability Factor |

|---|---|---|---|---|

| 3D Printing | Utilizes additive manufacturing for complex designs. | PLA (Polylactic Acid) | Medical devices, customized products. | Biodegradable |

| Injection Molding | High-volume production of detailed parts. | PP (Polypropylene) | Consumer goods, automotive components. | Recyclable |

| Bioplastic Development | Innovative materials derived from renewable resources. | PHA (Polyhydroxyalkanoates) | Food packaging, disposable items. | Compostable |

| Smart Plastics | Integrates sensors for enhanced functionality. | PC (Polycarbonate) | Smart packaging, IoT devices. | Energy-efficient |

| Reinforced Plastics | Materials enhanced with fibers for strength. | FRP (Fiber Reinforced Plastics) | Construction, aerospace applications. | Durable and long-lasting |

At the upcoming 2025 China Import and Export Fair, the focus on consumer demands is set to drive significant innovations in plastic parts. With the real estate sector witnessing rapid growth, boosted by increased demand for both office and residential spaces, the luxury furniture market is expanding concurrently. This trend highlights a burgeoning consumer interest in high-quality, aesthetically pleasing plastic components that enhance home and office environments. As reported, the automotive plastic composite market is also experiencing remarkable growth, influenced by manufacturers’ push towards lightweight materials to improve fuel efficiency.

Moreover, the flexible plastic packaging market is evolving in response to rising consumer demands for sustainable options. The increasing shift towards biodegradable packaging reflects a broader market trend where eco-friendly practices are prioritized. In 2023, forecasts estimated that the anti-oil paper market would grow from $111.78 million in 2025 to $213.58 million by 2033, showcasing an compound annual growth rate (CAGR) of 8.43%. These figures emphasize the vital role consumer preferences play in shaping innovation and market dynamics within the plastic industry, particularly at events like the China Import and Export Fair where emerging trends are highlighted.

The 2025 China Import and Export Fair has emerged as a significant platform for global collaborations in the development and trade of plastic parts. With the plastic industry projected to reach a global market value of $1 trillion by 2026, as per a recent report by Grand View Research, the fair brings together innovators, manufacturers, and stakeholders aiming to capitalize on lucrative international partnerships. Notably, the event highlights advancements in sustainable materials, reflecting a growing industry trend driven by consumer demand for eco-friendly solutions.

In collaboration with international firms, Chinese manufacturers are exploring new technologies that enhance the performance and durability of plastic components. According to the International Plastics Association, the shift towards bioplastics could account for approximately 25% of the market share by 2030, driving attentiveness to recycling and circular economy principles among partners. These collaborations not only foster innovation but also encourage knowledge exchange, ultimately benefiting the entire supply chain.

**Tips:** When exploring innovations in plastic parts, consider investing in partnerships that prioritize sustainable practices. Additionally, stay updated on regulatory changes that may impact the global trade landscape. Engaging in industry forums and networks can also provide valuable insights into best practices and emerging technologies.

This chart illustrates the innovation levels in various plastic parts manufacturing techniques showcased at the 2025 China Import and Export Fair, reflecting advancements in the industry and highlighting potential areas for global collaboration.