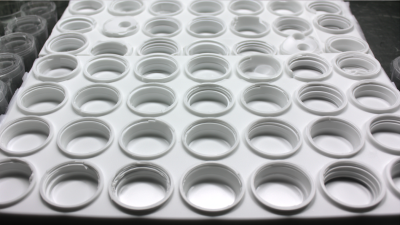

The plastic dip molding industry is poised for transformative growth, driven by advancements in technology and increasing demand across various sectors. According to a recent market research report by Grand View Research, the global plastic dip molding market is expected to reach USD 1.5 billion by 2027, growing at a CAGR of 5.6%. This growth is largely attributed to the expanding application of plastic dip molding in automotive, consumer goods, and electronics, as manufacturers seek more sustainable and cost-effective production methods.

Innovations in materials and processes, such as the adoption of eco-friendly resins and automated equipment, are shaping a more efficient and versatile manufacturing landscape. As the industry evolves, understanding these trends and innovations will be crucial for stakeholders looking to navigate the complexities of the market and harness opportunities for growth in the realm of plastic dip molding.

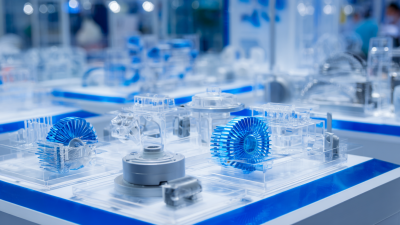

The landscape of plastic dip molding is undergoing significant transformation, driven by emerging technologies that are reshaping the industry. Automation and robotics are at the forefront, enhancing precision and efficiency in the molding process. These advancements not only streamline production but also reduce material waste, making the process more sustainable. Companies are increasingly adopting sophisticated machinery that utilizes artificial intelligence to monitor conditions in real-time, ensuring optimal outcomes and minimizing defects.

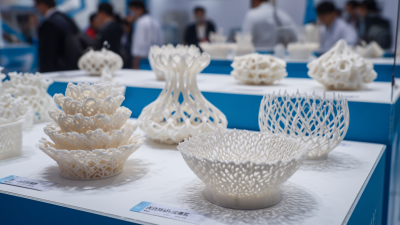

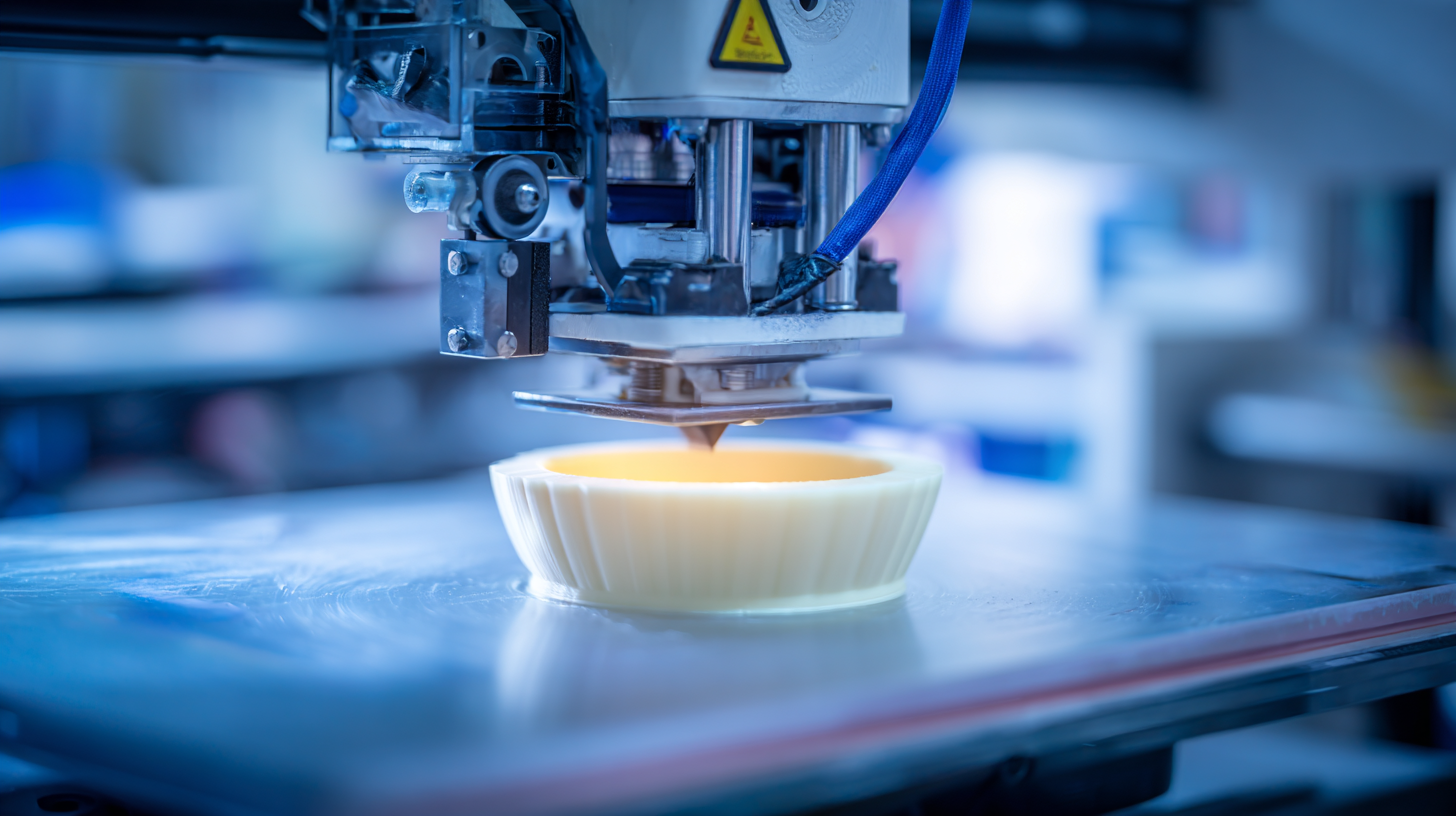

Additionally, innovative materials are entering the market, allowing for greater versatility in product design and functionality. Biodegradable plastics and advanced composites are being developed to meet the growing demand for sustainable solutions. This shift towards eco-friendly materials is complemented by the integration of 3D printing technologies, which facilitates rapid prototyping and customization of mold designs. As these technologies converge, they promise to elevate the capabilities of plastic dip molding, enabling the creation of more complex geometries and enhanced performance for a wide range of applications.

The plastic dip molding industry is experiencing significant transformation driven by several key market trends. One of the most notable trends is the increasing demand for environmentally friendly materials. Manufacturers are increasingly investing in sustainable practices and eco-friendly alternatives to traditional plastics to appeal to environmentally conscious consumers. This shift not only caters to market preferences but also aligns with global initiatives toward reducing plastic waste.

Another critical trend shaping the future of plastic dip molding is the advancement of technology. Innovative molding techniques and automation are enhancing production efficiency and reducing costs. These technological advancements enable manufacturers to produce more complex designs, improve product quality, and respond quickly to market needs. As companies continue to embrace smart manufacturing processes, we can expect a surge in customized and high-performance dip molded products.

Tips: When exploring the plastic dip molding market, consider integrating sustainable materials to meet the evolving demands of consumers. Also, keep an eye on the latest technological updates in the industry to ensure you are not falling behind competitors. Regularly collaborate with suppliers and invest in training for your workforce to maximize the benefits of new tools and techniques.

The landscape of plastic dip molding is rapidly evolving, driven by innovative materials that significantly enhance performance across various applications. Advancements in polymer technology have led to the development of high-performance thermoplastics, which offer improved durability, flexibility, and resistance to environmental stressors. These materials are not only lightweight but also exhibit exceptional chemical resistance, making them ideal for use in industries ranging from automotive to consumer goods.

Moreover, emerging sustainable materials are gaining traction within the plastic dip molding sector. Biodegradable polymers and recycled composites are being integrated into production processes, allowing manufacturers to reduce their environmental footprint while maintaining high-quality output. As companies increasingly prioritize sustainability, the incorporation of these innovative materials aligns with consumer demand for eco-friendly products, further reshaping the market dynamics. Thus, the future of plastic dip molding is poised to be defined not just by performance and versatility, but also by a commitment to sustainable practices.

In recent years, sustainability initiatives have become a driving force within the plastic dip molding industry, prompting manufacturers to reevaluate their practices and materials. The shift towards eco-friendliness is evident as companies increasingly adopt biodegradable and recyclable materials in their production processes. This not only reduces the environmental impact of plastic waste but also appeals to a growing consumer base that prioritizes sustainability in their purchasing decisions.

Moreover, innovative technologies are emerging, enabling more efficient use of resources during the manufacturing process. Techniques such as closed-loop systems minimize material waste and energy consumption, aligning with broader environmental goals. Additionally, partnerships between industry players and environmental organizations are fostering the development of greener practices, making it possible to implement new standards in plastic dip molding. As these initiatives continue to evolve, the industry is poised to transform its reputation and contribute positively to a more sustainable future.

The plastic dip molding industry is on the brink of transformative changes driven by advancements in materials and sustainability. One of the future challenges for manufacturers lies in adapting to stricter environmental regulations. As consumers become more eco-conscious, there is an increasing demand for biodegradable and recyclable materials, pushing manufacturers to innovate. This shift not only presents a challenge but also an opportunity for those who can develop sustainable practices and products that meet these new standards.

Tips for manufacturers looking to navigate this evolving landscape include investing in research and development to explore novel materials that align with sustainability goals. Collaborating with environmental organizations can also provide insights into effective practices and potential certifications that enhance brand value. Additionally, staying attuned to market trends and consumer preferences can help manufacturers tailor their offerings, ensuring they remain competitive while addressing the demands for eco-friendly solutions.

Embracing innovation while focusing on sustainability will be key for plastic dip molding manufacturers in seizing opportunities and overcoming future challenges.