In today's competitive manufacturing landscape, the importance of effective mold making techniques cannot be overstated. Mold making serves as the backbone of many production processes, directly influencing both the quality of the final product and the efficiency of the operation. As industries strive to improve their workflows and reduce costs, innovative mold making strategies have emerged as game-changers. This article delves into the transformative potential of advanced mold making methods, offering valuable tips and insights that can help optimize production. By adopting these techniques, manufacturers can enhance precision, improve turnaround times, and ultimately boost their bottom line. Embracing a more effective approach to mold making is not just a creative choice; it is an essential step toward achieving sustainable and scalable production success.

The process of mold making is pivotal in enhancing production efficiency across various industries. It serves as the backbone of manufacturing, enabling the creation of complex shapes and structures with precision. By investing in effective mold making techniques, companies can significantly reduce material waste and production time, ensuring that each cycle yields consistent quality. This efficiency not only cuts costs but also allows for quicker turnaround times, meeting the ever-increasing demand for rapid production without compromising on quality.

Moreover, understanding the intricacies of mold making helps manufacturers tailor their processes to better suit specific products. Advanced techniques, such as computer-aided design and rapid prototyping, provide the flexibility to iterate and refine designs before final production. This adaptability contributes to a more streamlined workflow, fostering innovation and enabling businesses to stay competitive in a fast-paced market. Ultimately, mastering mold making is key to unlocking higher productivity levels and sustaining growth in today’s manufacturing landscape.

The quality of molds significantly influences the fabrication process in various industries, particularly in manufacturing sectors like automotive and consumer goods. According to a report by Grand View Research, the global mold market is expected to reach $8.5 billion by 2025, highlighting the increasing importance of high-quality molds in production efficiency. Key techniques such as advanced CAD/CAM software and 3D printing are revolutionizing mold creation. These technologies enable manufacturers to create intricate designs with precision, reducing material waste by up to 30% and accelerating production timelines.

Another vital technique is the use of high-performance materials, such as aluminum and thermoplastics, which can enhance durability and reduce lead times. A study published by the American Society of Mechanical Engineers attributes a 20% improvement in cycle times to the implementation of these materials in mold design. Furthermore, regular maintenance and modern cooling strategies can optimize the thermal dynamics of molds, ensuring consistent product quality and minimizing defects. Adopting these innovative approaches not only streamlines the manufacturing process but also supports sustainability efforts by conserving resources and reducing environmental impact.

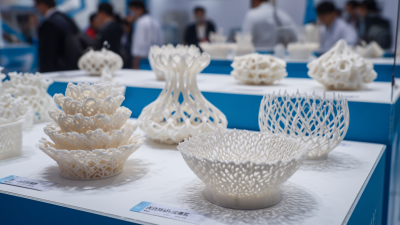

Innovative materials and technologies are playing a pivotal role in revolutionizing mold production, significantly enhancing both efficiency and quality in manufacturing processes. Advanced materials like silicone and thermoplastics are increasingly being used, offering superior durability and flexibility compared to traditional metals. These materials not only reduce production times but also allow for more complex and intricate mold designs that meet the evolving demands of various industries. The ability to produce light-weight yet strong molds enhances the overall product's performance while minimizing energy consumption during the production phase.

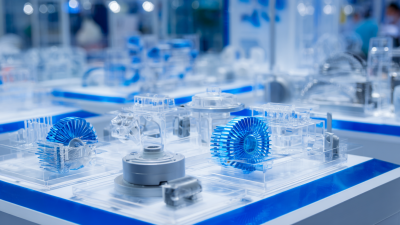

Furthermore, cutting-edge technologies such as 3D printing and computer numerical control (CNC) machining are streamlining the mold-making process. 3D printing enables rapid prototyping, allowing designers to quickly iterate their concepts and bring products to market faster. On the other hand, CNC machining provides precision and repeatability, ensuring that molds are manufactured to exact specifications. This integration of innovative materials and technologies ensures that manufacturers can not only meet current market demands but also stay ahead of the curve, driving transformation in their production processes.

| Technique | Material Type | Benefits | Production Efficiency (%) | Cost Reduction (%) |

|---|---|---|---|---|

| 3D Printing | Thermoplastics | Rapid Prototyping | 30% | 20% |

| CNC Machining | Aluminum | High Precision | 25% | 15% |

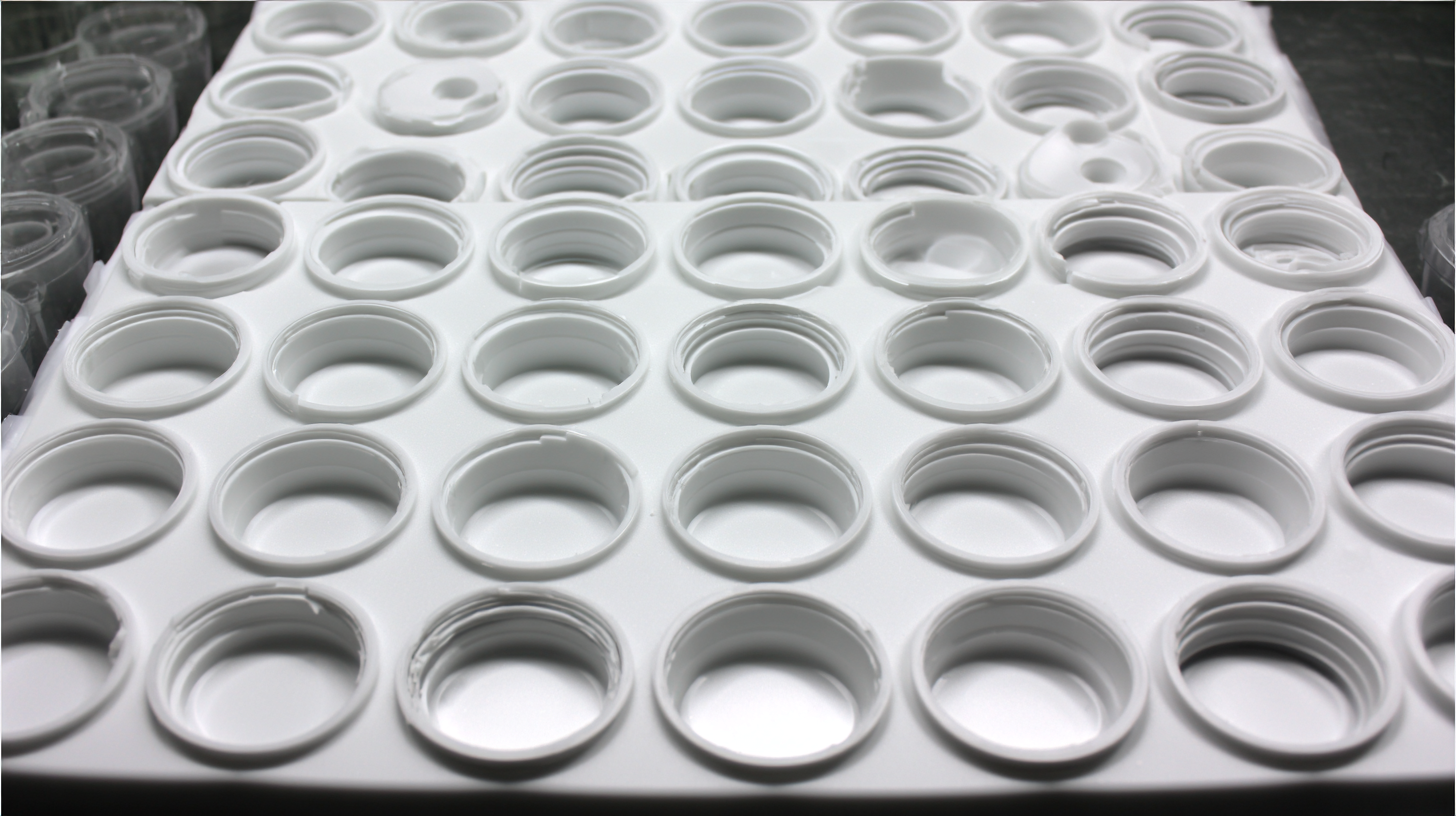

| Injection Molding | Polypropylene | Mass Production | 40% | 25% |

| Stereolithography | Resins | Detailed Features | 35% | 10% |

| Vacuum Forming | Acrylic | Low Volume | 20% | 5% |

Streamlining the mold making process is crucial for optimizing production efficiency and output quality. Advanced techniques, such as integrated automation and 3D printing, have emerged as pivotal strategies for manufacturers looking to enhance their capabilities. Reports indicate that automation in the manufacturing sector can lead to a reduction of production times by up to 30%, significantly increasing throughput while maintaining high precision in complex mold designs.

Utilizing sophisticated technologies, manufacturers can create molds with intricate cores and cavities that meet the demanding specifications of modern production. For instance, the adoption of AI-driven processes is revolutionizing the industry by enabling more responsive and smarter production methodologies. These innovations are not only improving efficiency but also empowering producers to adapt swiftly to consumer trends, thereby increasing product diversity without sacrificing quality.

**Tips for Streamlining Mold Making:**

1. Embrace automation and AI technologies to reduce manual errors and speed up production lines.

2. Invest in 3D printing capabilities to innovate mold designs and materials quickly.

3. Implement data-driven decision-making processes to enhance production workflows and adapt to market demands efficiently.

This chart illustrates the impact of various mold making techniques on production efficiency. As companies adopt more effective mold making strategies, they can significantly improve output and reduce cycle times.

Mold making is a critical process in manufacturing, yet it presents several challenges that can hinder efficiency and quality. One common issue is the precision required in creating molds. Even slight inaccuracies can lead to defects in the final product, resulting in costly rework or scrap. To overcome this, manufacturers are increasingly adopting advanced technologies such as 3D printing and CNC machining, which allow for higher accuracy and reduced lead times. By investing in these technologies, companies can improve their mold-making precision and enhance the overall production process.

Another significant challenge in mold making is material selection. Often, traditional materials may not meet the demands of modern production, leading to issues such as wear and tear. Utilizing innovative materials, like advanced composites or specialty steels, can improve mold durability and performance. Implementing rigorous testing and quality assurance during the material selection process ensures that molds can withstand the rigors of production. Emphasizing training for personnel on the latest materials and processes also plays a crucial role in overcoming these common challenges, ultimately leading to a more streamlined and effective production workflow.