Reinforced plastic has emerged as a transformative material in modern manufacturing, offering a unique combination of durability, lightweight properties, and resistance to environmental factors. As industries seek to innovate and improve efficiency, the versatility of reinforced plastic has made it an attractive alternative to traditional materials such as metals and wood. This introduction explores the various applications of reinforced plastic, highlighting its impact across different sectors ranging from automotive to aerospace.

The application of reinforced plastic in manufacturing not only enhances the performance and longevity of products but also contributes to sustainability efforts by reducing waste and energy consumption. By integrating reinforced plastic into their production processes, manufacturers can achieve significant weight savings without compromising structural integrity, making it a key material for the future. In this article, we will delve into the ten best uses of reinforced plastic, showcasing its potential to revolutionize manufacturing practices and drive technological advancements.

Reinforced plastic has become a cornerstone in automotive manufacturing, offering several advantages that enhance vehicle performance and safety. The lightweight nature of reinforced plastics contributes significantly to fuel efficiency, allowing manufacturers to create vehicles that consume less fuel without sacrificing strength. By incorporating materials such as fiberglass or carbon fiber into their designs, manufacturers can achieve a balance of durability and reduced weight, enabling better acceleration and handling.

One of the most exciting applications of reinforced plastic in the automotive sector is in the production of body panels and structural components. These materials can be molded into complex shapes, providing designers with greater flexibility and innovation in vehicle aesthetics. Moreover, reinforced plastic is resistant to corrosion and environmental degradation, which enhances the longevity of vehicle parts and reduces maintenance costs over time.

Tips: When considering the use of reinforced plastic in your projects, it is essential to evaluate the specific mechanical properties required. Always conduct thorough testing to ensure that the material meets safety standards and performance expectations. Additionally, collaborating with suppliers who specialize in reinforced plastics can help you discover new applications and innovative techniques to effectively integrate these materials into your designs.

Reinforced plastic has emerged as a revolutionary material in the aerospace industry, providing lightweight yet durable solutions for various components. One of the most innovative uses of reinforced plastic is in structural elements such as fuselage and wing parts. These materials, often composed of fiber-reinforced polymers, offer exceptional strength-to-weight ratios that significantly reduce the overall weight of aircraft. This weight reduction leads to improved fuel efficiency and enhances the performance of the aircraft while maintaining structural integrity under demanding conditions.

Additionally, reinforced plastics are utilized in the creation of interior components, such as seating and control panels. The design flexibility of these materials allows for intricate shapes and lightweight structures that can be easily customized to meet specific ergonomic and aesthetic requirements. Furthermore, the resistance to corrosion and environmental wear makes reinforced plastic a favorable choice for parts exposed to various atmospheric conditions, contributing to the longevity and reliability of aerospace systems. As innovation continues to drive advancements in materials science, reinforced plastics are likely to play an increasingly vital role in the future of aerospace manufacturing.

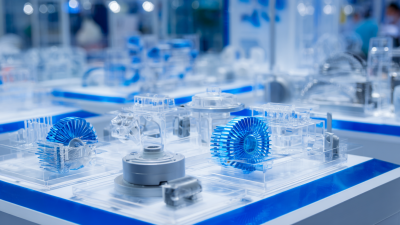

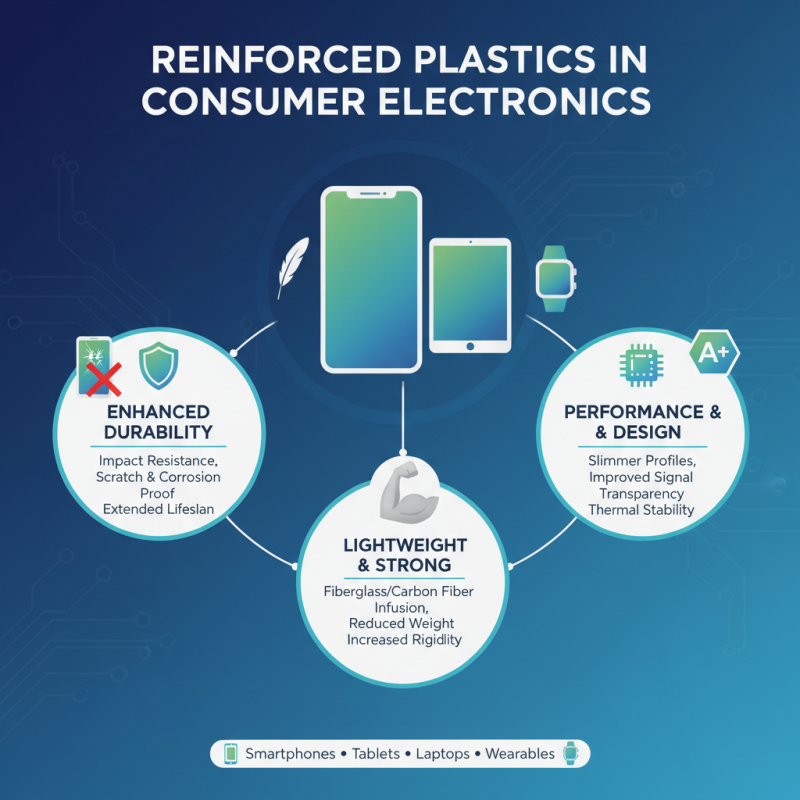

Reinforced plastic has become a transformative material in the realm of consumer electronics, enabling manufacturers to achieve superior performance and design advantages. The incorporation of fiberglass or carbon fibers into plastic matrices enhances strength and rigidity while maintaining a lightweight profile. This characteristic is crucial in the production of devices like smartphones and tablets, where reducing weight and increasing durability are paramount. The resilience of reinforced plastics also offers improved resistance to impacts, scratches, and corrosion, significantly extending the lifespan of electronic devices.

Additionally, the versatility of reinforced plastic allows for innovative design possibilities that were previously unattainable with traditional materials. Manufacturers can mold these plastics into complex shapes, allowing for sleek and ergonomic designs that enhance user experience. Moreover, reinforced plastics can be engineered to exhibit specific thermal and electrical properties, catering to a wide range of applications from housings to internal components. This adaptability not only bolsters aesthetic appeal but also contributes to enhanced functionality and efficiency, positioning reinforced plastic as a key player in the evolution of consumer electronics.

Reinforced plastic, notably in the form of fiber-reinforced polymer (FRP), has emerged as a critical material in construction and infrastructure projects. Its lightweight nature contributes significantly to reducing the overall project weight while maintaining high strength-to-weight ratios. According to a report by MarketsandMarkets, the global FRP composite market is expected to reach $105.5 billion by 2025, reflecting a growing adoption in sectors such as civil engineering and construction. This growth is largely attributed to reinforced plastics’ superior corrosion resistance, which outperforms traditional materials like steel and concrete, particularly in harsh environmental conditions.

Additionally, the durability of reinforced plastic contributes to longer life cycles for infrastructure components, translating into cost savings over time. A study by the American Composites Manufacturers Association indicates that using FRP in construction can lead to a 30% decrease in long-term maintenance costs. Furthermore, the material's ability to be molded into complex shapes allows for innovative architectural designs that would be difficult to achieve with conventional materials. As more engineers and architects become aware of these advantages, the integration of reinforced plastics in modern manufacturing continues to transform the landscape of construction and infrastructure development.

Reinforced plastics have emerged as a game-changing solution in modern manufacturing, particularly in the realm of sustainability. With the global demand for eco-friendly materials on the rise, reinforced plastics have become a preferred choice due to their lightweight properties and durability. According to a recent report by the Ellen MacArthur Foundation, the plastics industry generates 300 million tons of plastic annually, and a significant shift towards reinforced plastics can help mitigate environmental impacts by enhancing recycling and reducing waste. This material supports the circular economy model, where products are designed for longevity and reusability, thus decreasing the carbon footprint associated with traditional manufacturing processes.

Furthermore, a study by the Global Composites Market indicates that the reinforced plastic market is projected to reach $152 billion by 2027, emphasizing its growing acceptance in sectors like automotive, aerospace, and construction. Companies are increasingly adopting reinforced plastics not only to meet regulatory demands but also to fulfill consumer expectations for sustainable practices. For instance, reinforced plastics can facilitate energy savings, with composites being lightweight, which further reduces energy consumption during transportation. The transition to reinforced plastics in green manufacturing solutions exemplifies how the industry is pivoting toward innovative, sustainable practices that align with environmental goals.

| Application | Description | Environmental Benefits | Durability |

|---|---|---|---|

| Automotive Parts | Used for manufacturing lightweight and corrosion-resistant components. | Reduces fuel consumption and emissions. | High impact resistance and longevity. |

| Construction Materials | Utilized in beams, panels, and roofing solutions. | Sustainable building materials reduce waste and energy usage. | Superior weather resistance and structural integrity. |

| Aerospace Components | Lightweight and strong materials for aircraft parts. | Minimizes carbon footprint during flights. | Exceptional fatigue resistance. |

| Consumer Products | Used in packaging, electronics, and appliances. | Recyclable materials contribute to a circular economy. | Long-lasting and resistant to wear. |

| Marine Applications | Used in boat hulls, decks, and equipment. | Reduces the need for heavy and less sustainable materials. | Resistant to water and marine environments. |

| Electrical Insulation | Provides insulation for wires and components. | Contributes to energy efficiency in electrical systems. | Resistance to heat and chemicals. |

| Medical Devices | Materials used in the production of surgical instruments and implants. | Encourages the use of eco-friendly materials in healthcare. | Durable and biocompatible. |

| Furniture Design | Innovative designs utilizing reinforced plastic. | Sustainable sourcing and production methods. | Strong and lightweight, ideal for modern aesthetics. |

| Textile Industry | Usage in durable woven fabrics and composites. | Promotes sustainable textile practices. | Provides strength and resistance to different climates. |

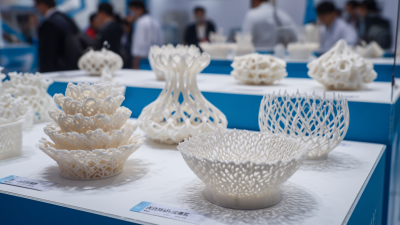

| 3D Printing Materials | Focus on sustainable, reinforced printing filaments. | Encourages recycling and innovation in manufacturing. | High strength-to-weight ratio for various applications. |