In 2023, the plastic dip molding industry has garnered significant attention due to its expanding applications across various sectors, including automotive, consumer goods, and electronics. The flexibility, durability, and cost-effectiveness of plastic dip molding processes are positioning them as a go-to solution for manufacturers seeking to innovate while maintaining efficiency. According to a report by Market Research Future, the global plastic dip molding market is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2022 to 2030, reflecting the rising demand for custom molded products.

Notably, industry expert Dr. Emily Hargrove, a leading authority in polymer materials, states, “The versatility of plastic dip molding is revolutionizing the way businesses approach product design and functionality.” Her insights highlight the transformative potential of this technology, especially as industries increasingly focus on sustainability and customized solutions. As we explore the top five benefits of plastic dip molding in this article, we will delve into how these trends are shaping the future landscape of manufacturing, illustrating why companies should prioritize adopting this innovative method in their production strategies.

In 2023, plastic dip molding continues to emerge as a preferred manufacturing method across various industries due to its unique advantages. One significant benefit is the ability to create complex shapes with a high degree of precision. According to a recent report by Grand View Research, the global plastic mold market is expected to reach $18.4 billion by 2025, driven largely by the growing demand for high-quality, customized products. This trend highlights the importance of techniques like plastic dip molding that can efficiently produce intricate designs while maintaining cost-effectiveness.

Another notable advantage of plastic dip molding is its versatility in material selection. Manufacturers can choose from a wide range of thermoplastics, enabling tailored solutions for specific applications. Data from Statista indicates that thermoplastics account for over 60% of the global plastic production, underscoring their critical role in modern manufacturing. Moreover, the process offers excellent surface finishes and enhances the durability of the final product, making it suitable for demanding environments in sectors such as automotive and aerospace. These factors collectively position plastic dip molding as a valuable technique in 2023, appealing to businesses aiming for innovation and sustainability in their production processes.

Plastic Dip Molding has gained significant traction in modern manufacturing due to its cost-effectiveness, presenting an attractive option for businesses looking to optimize their production processes. According to a recent market analysis report by Smithers Pira, the global plastic molding market is projected to reach $500 billion by 2025, with dip molding being one of the fastest-growing segments. This technique not only reduces material wastage—estimated to be about 15% less than traditional methods—but also streamlines production timelines, making it possible for companies to respond swiftly to market demands.

Cost analysis shows that dip molding can yield substantial savings over time. A report from the American Injection Molding Institute indicates that organizations utilizing this method often experience at least a 20% reduction in manufacturing costs when compared to other molding techniques, such as injection or blow molding. Additionally, the versatility of materials used in plastic dip molding allows for customization without incurring significant extra costs. This flexibility empowers manufacturers to innovate without the burden of high investment, making dip molding an increasingly popular choice in a competitive industry landscape.

In 2023, sustainability trends are significantly reshaping the plastic dip molding industry. As environmental concerns become increasingly paramount, manufacturers are exploring eco-friendly materials and processes. The shift towards sustainable practices is evident in the adoption of biodegradable compounds and recycled plastics, which not only reduce waste but also mitigate the carbon footprint associated with traditional plastic production methods. This transition aligns with global initiatives aimed at minimizing environmental impact, making plastic dip molding a more attractive option for environmentally conscious businesses.

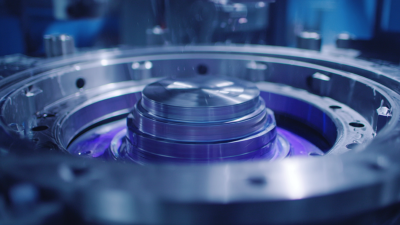

Moreover, companies are investing in innovative technologies that enhance the efficiency of plastic dip molding while adhering to sustainability standards. Advanced techniques such as energy-efficient heating and closed-loop systems are being implemented to conserve energy and reduce emissions throughout the manufacturing process. The emphasis on sustainability is fostering a new competitive landscape, where businesses that prioritize eco-friendly practices stand to gain a significant market advantage. The trend signifies a broader industry commitment to sustainability, reflecting changing consumer demands and regulatory requirements as society increasingly values environmental responsibility.

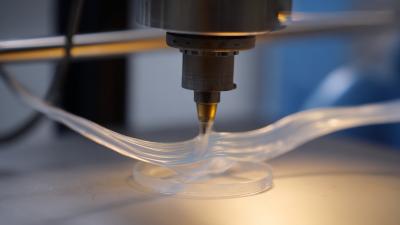

The landscape of plastic dip molding is evolving rapidly in 2023, driven by innovative technologies that enhance performance and efficiency. One of the most significant advancements is the development of advanced polymer formulations, which improve the mold's resistance to chemicals, temperatures, and wear. As manufacturers seek to increase their production capabilities, these formulations allow for faster curing times and better overall designs, leading to higher quality end products.

When considering a transition to modern plastic dip molding technologies, it is essential to keep a few tips in mind. Always evaluate the specific requirements of your application to choose the right polymer blend, as it can dramatically impact the final product’s durability. Additionally, investing in up-to-date molding equipment will not only streamline the production process but also reduce waste, which is crucial for operational sustainability.

Moreover, the integration of automation in the molding process has been a game-changer in enhancing consistency and precision. Embracing these innovations can lead to significant cost savings and improved turnaround times, allowing businesses to remain competitive in an ever-changing market. As industry professionals continue to explore these advancements, the future of plastic dip molding seems promising, with limitless possibilities for enhanced applications.

| Benefit | Description | Impact on Industry |

|---|---|---|

| Cost Efficiency | Lower material costs compared to traditional molding processes | Increased profit margins for manufacturers |

| Design Flexibility | Ability to create complex shapes and configurations | Enhanced creativity in product development |

| Durability | Improved resistance to environmental factors and wear | Increased product lifespan and lower replacement costs |

| Rapid Production | Faster cycle times allow for quicker product launches | Competitive advantage in fast-paced markets |

| Sustainability | Utilization of recyclable materials and reduced waste | Alignment with green manufacturing practices |

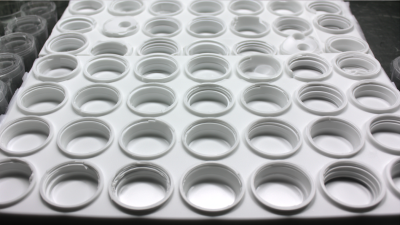

In 2023, plastic dip molding continues to make significant strides across various key industries, showcasing its versatility and efficiency. The healthcare sector, in particular, has greatly benefited from advancements in plastic molding techniques. With approximately 30% of medical devices now being produced using advanced plastics, this trend underlines the importance of reliable and cost-effective molding solutions. Innovations in this field have enabled the production of critical medical tools such as syringes, IV bags, and surgical gloves, all of which require precision and durability that plastic dip molding offers.

Another industry reaping the rewards of plastic dip molding is automotive manufacturing. As market demands shift, manufacturers are increasingly looking for lightweight yet robust components to enhance vehicle performance and fuel efficiency. A recent report indicates that lightweight plastics can reduce vehicle weight by up to 20%, contributing to improved fuel economy. The growing focus on sustainability has further accelerated the shift towards plastic solutions, as these materials not only meet the performance requirements but also align with environmental considerations that are paramount in today’s automotive designs. With industry leaders emphasizing innovation, plastic dip molding is poised to remain a crucial asset as businesses adapt to evolving market trends.

This chart illustrates the top five benefits of plastic dip molding in 2023, highlighting how industries leverage these advantages to optimize their production processes.