Over molding has emerged as a powerful technique in the realm of product manufacturing, combining two or more materials to create a single, cohesive component. This innovative process not only enhances the functionality of a product but also contributes significantly to its aesthetic appeal and longevity. By allowing manufacturers to integrate various materials with different properties, over molding opens up a world of possibilities for creating custom solutions tailored to specific needs.

In an increasingly competitive market, finding ways to improve product performance while reducing costs is paramount. Over molding stands out as a beneficial approach that not only maximizes efficiency but also minimizes the need for additional assembly, ultimately streamlining the manufacturing process. The advantages of over molding extend beyond mere cost savings; they include improved tactile experiences, enhanced durability, and increased design flexibility.

As we delve into the top ten benefits of over molding, we will explore how this method can transform product development, drive innovation, and provide manufacturers with a distinct edge in delivering high-quality, reliable products. By understanding the advantages of over molding, businesses can make informed decisions that bolster their production capabilities and satisfy their customers’ evolving preferences.

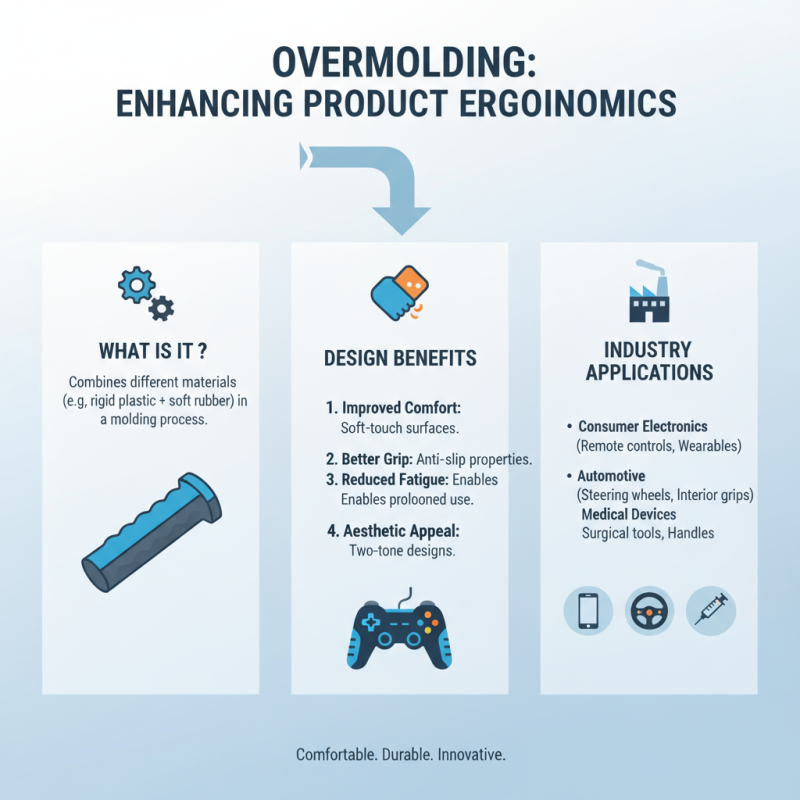

Over molding is a versatile manufacturing process that combines two or more materials to create a single, unified product. This technique offers several advantages, particularly in the realm of product manufacturing. One of the primary benefits of over molding is enhanced ergonomics; by incorporating softer materials, manufacturers can design products that fit comfortably in the user's hand, significantly improving the user experience. Additionally, over molding enables better grip and traction, which is crucial for tools and devices that require a secure hold.

Another valuable benefit of over molding is the increased durability it provides. By bonding two materials, such as rigid plastics and flexible elastomers, manufacturers can produce products that withstand wear and tear while maintaining functionality. This not only extends the lifespan of the product but also reduces the likelihood of breakage or damage, making it a cost-effective option in the long run. Furthermore, over molding allows for improved aesthetics; manufacturers can use different colors and textures to enhance the visual appeal of their products, making them more attractive to consumers in a competitive market.

| Benefit | Description | Application |

|---|---|---|

| Enhanced Grip | Over molding improves the tactile feel for better usability. | Handheld devices, tools |

| Aesthetic Appeal | Allows for better color and design finishes for a more attractive product. | Consumer electronics, fashion items |

| Multiple Materials | Combines hard and soft materials for versatile functionality. | Medical devices, automotive parts |

| Cost Efficiency | Reduces assembly costs by integrating multiple components. | Consumer goods manufacturing |

| Impact Resistance | Enhances durability against drops and impacts. | Electronics, outdoor equipment |

| Heat Insulation | Provides resistance to high temperatures, enhancing safety. | Appliances, automotive interiors |

| Waterproofing | Creates seals that protect against water penetration. | Outdoor gear, electronic enclosures |

| Customization | Facilitates tailored solutions to meet specific customer needs. | Specialty tools, niche market products |

| Reduced Wear and Tear | Minimizes friction and surface wear for longevity. | Moving parts, mechanical assemblies |

| Simplified Manufacturing Process | Streamlines production by reducing the number of necessary processes. | Mass production, assembly lines |

Over molding techniques significantly enhance product durability, offering a robust solution for various manufacturing needs. By incorporating two or more materials during the production process, over molding creates a bonded structure that combines the strengths of both materials. This results in a finished product that not only withstands physical stress but is also resistant to environmental factors such as moisture, heat, and chemical exposure. As a result, products made through over molding tend to have a longer lifespan, reducing the need for frequent replacements and repairs.

The combination of different materials in over molding also allows for improved grip and user experience, reducing slippage and enhancing comfort during use. For example, a hard, rigid core can be enveloped in a softer, rubber-like exterior, providing a tactile experience that is both pleasing and functional. This method not only contributes to the aesthetic appeal of products but also reinforces their structural integrity. Consequently, over molding is a strategic choice for manufacturers looking to deliver high-quality, durable products in competitive markets.

Over molding has emerged as a pivotal manufacturing technique, particularly known for its cost efficiency in reducing production waste. By combining two or more materials in a single process, over molding not only enhances the performance and aesthetics of products, but it also minimizes material waste associated with traditional manufacturing methods. According to a recent industry report by the Society of Plastics Engineers, adopting over molding can lead to a reduction in scrap material by up to 35%. This not only diminishes environmental impact but also offers significant cost savings in the production cycle.

Tips: When implementing over molding, consider utilizing advanced simulation software to optimize your designs. This tool can help identify potential waste areas before production begins, ensuring that resources are used efficiently. Additionally, select materials that complement each other well; this synergy can further reduce the need for secondary processes, ultimately lowering production costs.

Moreover, over molding can streamline the manufacturing process by combining several assembly steps into one. This approach reduces labor costs and accelerates time-to-market for new products. The report highlights that manufacturers employing this technique can see cycle time reductions of approximately 20-30%. By integrating parts and simplifying the manufacturing process, companies can focus on enhancing product quality while enjoying lower operational expenses.

Tips: Regularly review and update your manufacturing approach based on the latest industry findings and reports. Staying informed about new materials and techniques can help you continuously optimize your production efficiency and cost-effectiveness.

Over molding is a manufacturing technique that significantly enhances the ergonomics of product design. By combining different materials, it allows for the creation of products that not only look appealing but also feel comfortable and natural in the hand. The outer layer's soft-touch materials can reduce user fatigue, enabling prolonged use without discomfort. This crucial aspect is vital in industries such as consumer electronics, automotive, and medical devices, where user interaction is frequent and prolonged.

Moreover, over molding provides the opportunity to tailor products to fit the contours of the human body more ergonomically. This is achieved through careful design and material selection, ensuring that every curve and grip point aligns with user needs. Enhanced grip and control can lead to improved performance and satisfaction, particularly in tools and equipment that require precision. By prioritizing ergonomic design through over molding, manufacturers can create products that improve user experience while also reducing the risk of strain or injury over time.

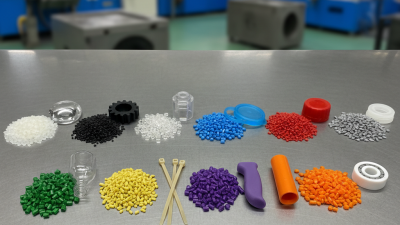

Over molding is a revolutionary technique in product manufacturing that enhances the compatibility of various materials, thereby broadening design possibilities. One of the primary advantages of this process is its ability to combine different polymers, enabling designers to leverage distinct material properties to create products that are both functional and aesthetically pleasing. For instance, soft-touch materials can be over molded onto harder substrates, resulting in products that offer improved grip and comfort while maintaining structural integrity. This versatility allows for innovative designs tailored to specific user needs, making over molding an invaluable process in developing consumer products.

Moreover, the capability to incorporate diverse materials extends beyond simple aesthetic adjustments; it includes the integration of advanced functionalities. Engineers can combine conductive materials for electronic components, such as shielding or electrical connections, with non-conductive outer layers that enhance durability and protection. This convergence of materials can lead to the creation of more compact and efficient products, satisfying both performance and safety requirements. Ultimately, over molding not only reduces manufacturing complexity by minimizing assembly steps but also fosters creativity in design, empowering manufacturers to push the boundaries of what’s possible in product development.