Silicone dip molding is rapidly gaining traction in various manufacturing sectors due to its versatility, efficiency, and the high-quality finishes it can produce. As reported by the Global Silicone Market Study, the silicone industry is projected to reach $22.4 billion by 2025, reflecting a growing demand for innovative molding techniques.

Silicone dip molding serves as a pivotal method in producing intricate parts across diverse industries, including automotive, aerospace, and consumer goods.

Renowned expert Dr. Emily Chen, a leading authority in polymer processing, underscores the importance of this technique, stating, "Silicone dip molding not only enhances the durability and functionality of products but also allows for remarkable design flexibility." This introduction of silicone dip molding techniques is critical for manufacturers seeking to optimize production processes while meeting stringent quality standards.

Renowned expert Dr. Emily Chen, a leading authority in polymer processing, underscores the importance of this technique, stating, "Silicone dip molding not only enhances the durability and functionality of products but also allows for remarkable design flexibility." This introduction of silicone dip molding techniques is critical for manufacturers seeking to optimize production processes while meeting stringent quality standards.

As we delve into the myriad applications and methods of silicone dip molding in this guide, we will explore how industry leaders are leveraging these advancements to remain competitive in the fast-evolving market landscape.

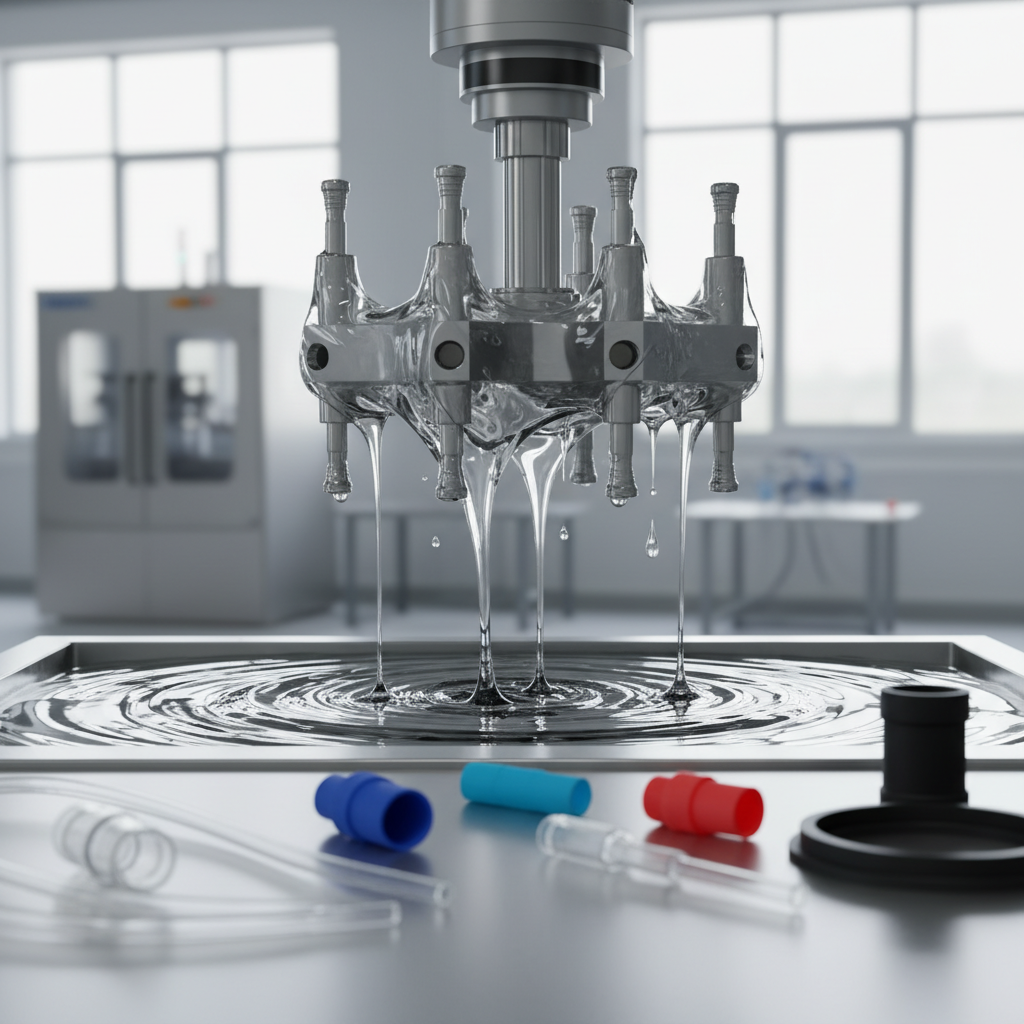

Silicone dip molding is a versatile manufacturing technique characterized by its process of immersing a mold in liquid silicone, allowing for the creation of complex shapes and designs. This method starts with the preparation of a mold, often crafted from materials like acrylic, which is suitable for both industrial and DIY applications. Once the mold is coated with a release agent, it is dipped into liquid silicone, allowing an even layer to adhere to its surface. Following a curing process, which can involve heating or chemical reactions, the silicone component is removed, resulting in flexible, durable products that can be used in various applications.

Recent advancements in silicone dip molding have expanded its utility in the production of consumer electronics, such as custom silicone keyboards that blend aesthetics and functionality. Additionally, the technique is integral to the field of special effects, where artists create lifelike prosthetics and props. As the boundary between consumer and professional-grade applications blurs, silicone dip molding represents a crucial link, allowing for high-quality, customized solutions in both creative and industrial contexts. This method showcases the potential of silicone materials, which can be molded into soft robotics as well, highlighting their adaptability and the innovative possibilities that arise from their usage.

Silicone dip molding is a versatile manufacturing process that offers a wide range of applications across different industries. Understanding the essential materials used in this technique is crucial for achieving desired results. Primarily, silicone elastomers are the main materials utilized due to their excellent thermal stability, chemical resistance, and flexibility. These properties make silicone an ideal choice for producing parts that require durability and resilience against environmental factors.

In addition to silicone elastomers, the choice of fillers can significantly influence the final product's characteristics. Fillers such as fiberglass and carbon black are commonly added to enhance the mechanical strength and improve thermal conductivity of the molded parts. Moreover, various additives are employed to achieve specific attributes, including flame retardants, colorants, and UV stabilizers. The compatibility of these materials with silicone is essential to maintain the integrity and performance of the final product, ensuring that it meets specific application requirements while operating under various conditions.

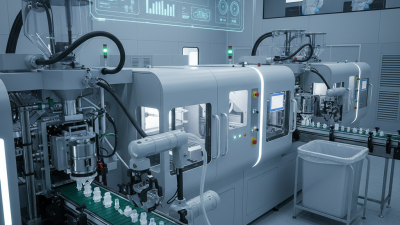

Silicone dip molding is a versatile technique widely utilized across various industries, offering unique benefits such as enhanced durability and flexibility. The process involves submerging a mold into liquid silicone, allowing it to coat the surface and create a uniform layer upon cooling. According to a recent industry report by MarketsandMarkets, the global silicone market is expected to grow from $20.7 billion in 2020 to $28.3 billion by 2025, driven significantly by the increasing demand for silicone-based products across sectors like automotive, electronics, and healthcare.

When engaging in silicone dip molding, following a systematic approach is crucial to achieving optimal results. Begin by preparing the mold—cleaning and applying a release agent enhances the smoothness and consistency of the final product. Carefully submerge the mold into the silicone, ensuring it is adequately coated. Allow it to cure fully to maintain structural integrity.

**Tips:** To optimize adhesion, maintain consistent temperatures during curing. Additionally, experiment with varying silicone viscosities for different applications to better suit your project needs. Always monitor the environment for contaminants, which could compromise the quality of the mold. Embracing these practices can significantly enhance the effectiveness of your silicone dip molding process.

Silicone dip molding techniques have gained significant traction across various industries, serving essential functions in manufacturing processes. This technique is particularly valuable in producing protective coatings, moldings, and insulation components. In sectors like automotive and electronics, silicone dip molded products enhance durability and resistance to extreme conditions. For instance, the automotive industry utilizes silicone dip molding for applications such as gaskets and seals, which require resilience against heat and chemicals.

Additionally, the market for complementary materials such as fatty acid amides, which are utilized as lubricants in the polymer sector, is projected to grow significantly by 2032. These compounds, derived from long-chain fatty acids, play a crucial role in enhancing the processability of silicone and other polymers during dip molding. Reports suggest that with the increasing demand for high-performance materials, the fatty acid amide market is expected to reach substantial market sizes, thereby further supporting the silicone dip molding industry. The synergy between these materials and silicone processing techniques underscores their importance in driving innovations across various applications, from household goods to advanced industrial components.

| Industry | Common Applications | Benefits of Silicone Dip Molding |

|---|---|---|

| Automotive | Protective grips and handles, vibration dampeners | Durability, heat resistance, and excellent grip |

| Electronics | Coatings for electrical components, insulators | Electrical insulation, moisture resistance |

| Medical | Surgical tools handles, medical device casings | Biocompatibility, easy to clean and sterilize |

| Consumer Goods | Kitchen utensils, toys | Non-toxic, flexibility, and variety of colors |

| Aerospace | Sealants, insulation for electronic parts | Lightweight, high thermal stability |

When engaging in silicone dip molding, achieving optimal results can sometimes be a challenge. One common issue is the adherence of the silicone to the mold, which can be mitigated by selecting the right release agents. It's crucial to use a release agent that is compatible with both the silicone and the mold material to prevent any sticking. Additionally, ensuring that the mold is clean and well-maintained can significantly enhance the quality of the final product.

Temperature control is another vital factor in optimizing silicone molding outcomes. Excessive heat can lead to premature curing or defects in the molded part. Therefore, monitoring the temperature of both the silicone material and the environment is essential. Using temperature-controlled ovens for curing processes can ensure uniform results. Furthermore, adjusting the thickness of the silicone layer can help manage curing times and material performance, leading to a more durable final product. Proper troubleshooting of these factors can greatly improve the overall efficiency and quality of silicone dip molding operations.